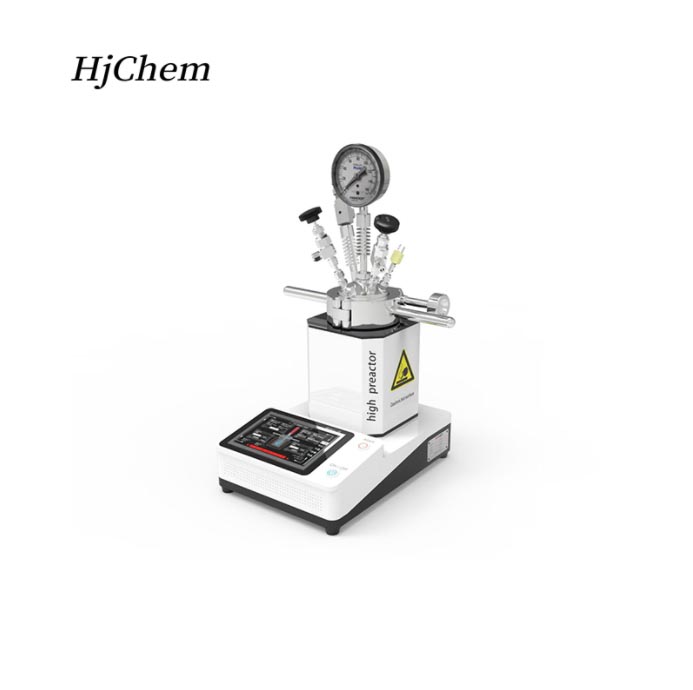

The Quick-Open Magnetic Stirring High Pressure Laboratory Reactor is an advanced, premium-engineered for rapid, safe, and efficient high-P/T experiments.

Basic Technical Specifications:

1. Volume: 10/25/50/100/250/500ml (customizable)

2. Material: 316L (other special materials customizable)

3. Structure: Quick-Open type

4. Temperature: RT-300°C (customizable)

5. Pressure: -0.1-10MPa (customizable)

6. Agitation Method: magnetic bar stirring

7. Valves: Two 1/4″ ferrule valve

8. Heating Power: 1000W-1500W

9. Power Supply: AC220V, 50HZ/60HZ

10. Control: Touch screen control

Expandable Functions:

1. Isobaric Feeding: Add liquid reactants during reaction (controlled total volume)

2. High-Pressure Feed Pump: Introduce liquid reactants during reaction (precise flow rate control)

3. Gas Mass Flow Meter: Accurately measure cumulative gas flow and instantaneous flow rate

4. Built-in Cooling Coil: Enables rapid internal reactor cooling

5. Condenser: Provides condensation reflux or solvent recovery functionality

Features:

1. Radical Time Savings

1.1 Quick-Open Flange System: Change samples in ≤2 minutes (vs. 30+ mins for bolt-sealed reactors).

1.2 Zero Cooling/Wait Times: Unique design enables immediate access post-reaction.

2. Uncompromised Mixing Performance

2.1 Sealed Magnetic Drive: Achieve homogeneous stirring up to 1,500 rpm under extreme pressure (100 bar+/300°C+)—critical for viscous slurries or gas-liquid reactions.

2.2 Zero Leak Risk: Eliminate rotating shaft seals that degrade under high-P/T conditions.

3. Material Versatility

3.1 Corrosion-Resistant Build: Options include SS316, Hastelloy C-276, or PTFE-lined vessels for acids/alkalis.

3.2 Broad Compatibility: Ideal for hydrogenation, hydrothermal synthesis, nanoparticle growth & polymerization.

4. Seamless Process Control

4.1 Sensor-Ready Ports: Direct integration with PT100 thermocouples, pressure transducers & data loggers.

4.2 Benchtop Scalability: Available in multiple volumes for process development.

For more information, please visit:

Magnetic Stirring High Pressure Lab Reactor Vessel

bio-equip.cn