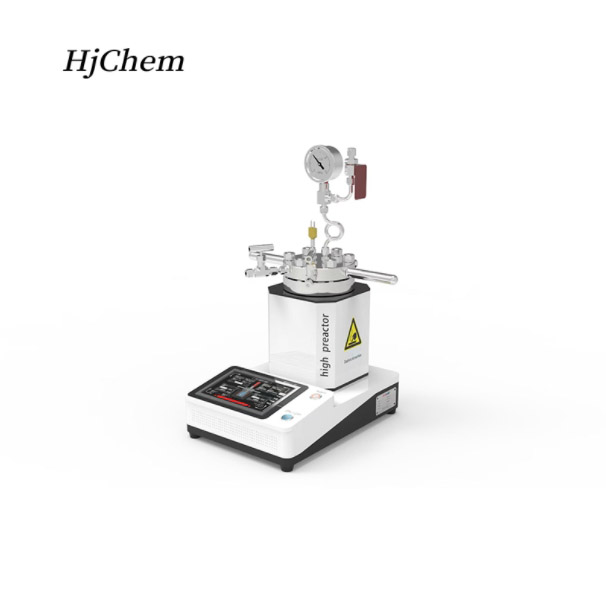

A High Pressure Lab Reactor is an advanced vessel engineered to conduct chemical reactions under elevated pressures and temperatures.

Basic Technical Specifications:

1. Volume: 10/25/50/100/250/500ml (customizable)

2. Material: 316L (other special materials customizable)

3. Structure: Flange type

4. Temperature: RT-300°C (customizable)

5. Pressure: -0.1-10MPa (customizable)

6. Agitation Method: Magnetic stirring

7. Valves: Two 1/4″ ferrule valve

8. Heating Power: 1000W-1500W

9. Power Supply: AC220V, 50HZ/60HZ

10. Control: Touch screen control

Expandable Functions:

1. Isobaric Feeding: Add liquid reactants during reaction (controlled total volume)

2. High-Pressure Feed Pump: Introduce liquid reactants during reaction (precise flow rate control)

3. Gas Mass Flow Meter: Accurately measure cumulative gas flow and instantaneous flow rate

4. Built-in Cooling Coil: Enables rapid internal reactor cooling

5. Condenser: Provides condensation reflux or solvent recovery functionality

Why "Magnetic Stirred"?

Our reactor integrates sealless magnetic stirring—a critical feature that:

1. Eliminates leakage risks (no rotating shafts penetrating the vessel).

2. Ensures homogeneous mixing of viscous or multiphase reactants.

3. Enables contamination-free reactions (ideal for sensitive catalysis/polymerization).

Unlike standard reactors, it simulates industrial-scale processes in a compact, lab-safe design—ideal for R&D in pharmaceuticals, catalysis, energy, and advanced materials.

For more information, please visit us:

High pressure reactor manufacturer

Magnetic Stirred High Pressure Lab Reactor

bio-equip.cn