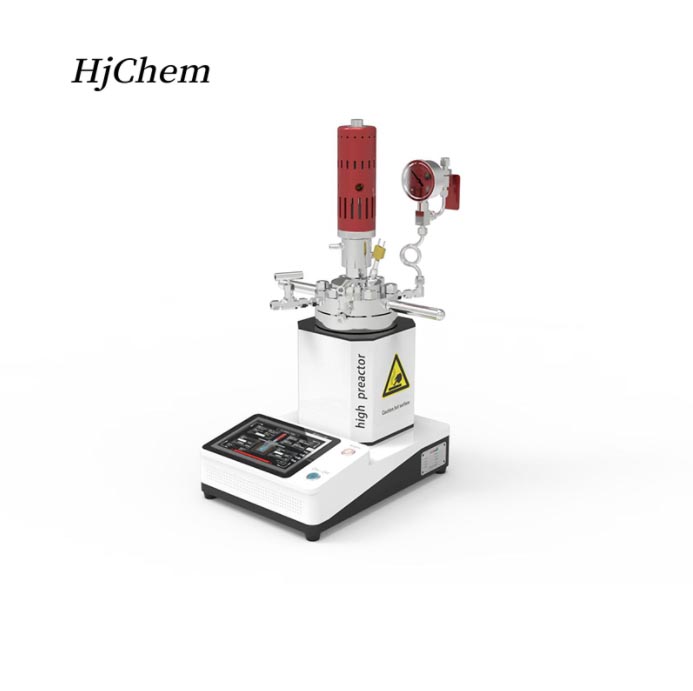

This compact high pressure stirred lab autoclave engineered for demanding chemical synthesis, materials research, and process development.

Basic Technical Specification:

1. Volume: 10/25/50/100/250/500ml (customizable)

2. Material: 316L (other special materials customizable)

3. Structure: Flange type

4. Temperature: RT-300°C (customizable)

5. Pressure: -0.1-10MPa (customizable)

6. Agitation Method: mechnical stirring

7. Valves: Two 1/4″ ferrule valve

8. Heating Power: 1000W-1500W

9. Power Supply: AC220V, 50HZ/60HZ

10. Control: Touch screen control

Expandable Functions:

1. Isobaric Feeding: Add liquid reactants during reaction (controlled total volume)

2. High-Pressure Feed Pump: Introduce liquid reactants during reaction (precise flow rate control)

3. Gas Mass Flow Meter: Accurately measure cumulative gas flow and instantaneous flow rate

4. Built-in Cooling Coil: Enables rapid internal reactor cooling

5. Condenser: Provides condensation reflux or solvent recovery functionality

Features:

1.Industrial Safety in Compact Form:

1.1 Robust Flange Seal Design: Unlike threaded closures, the flange with high-strength bolts provides superior, leak-proof containment at extreme pressures (typically up to 10 MPa / 100 bar) and temperatures (up to 300°C+).

1.2 Built-in Safety Features: Engineered with overpressure protection for critical experiments.

2.Precision Mixing Under Pressure:

2.1 Integrated Mechnical Stirring: Ensures efficient, homogeneous mixing of viscous solutions, slurries, or catalysts while under high pressure – essential for reproducible kinetics and nanoparticle synthesis.

2.2 Consistent Reaction Control: Eliminate stratification and achieve optimal mass/heat transfer even in demanding processes.

3.Benchtop Efficiency:

3.1 Space-Saving Design: Fits standard lab benches, eliminating the need for large floor-standing reactors. Ideal for labs with limited space.

3.2 Quick Assembly & Operation: Flange design allows faster loading/unloading compared to traditional threaded reactors.

4.Material Versatility &Compatibility:

4.1 Corrosion-Resistant Options: Available with SS316, Hastelloy liners, or PTFE inserts to handle acids, alkalis, and aggressive chemistries.

4.2 Wide Application Range: Perfect for catalysis (hydrogenation, polymerization), hydrothermal synthesis, nanomaterials R&D, fuel studies, and high-pressure solubility testing.

5.Enhanced Process Control:

5.1 Compatible with Automation: Easily integrates with temperature controllers, pressure sensors, and data logging systems for precise experiment monitoring & repeatability.

For more information, please visit us:

Reactor pressure vessel manufacturer

High Pressure Stirred Lab Autoclave

bio-equip.cn