Sample Processing :

Stirrers / Mixers

Homogenizers / Milling

Shakers / Oscillators

Ultrasonic / Cell Disruption

Pipettors

Other Sample Processing

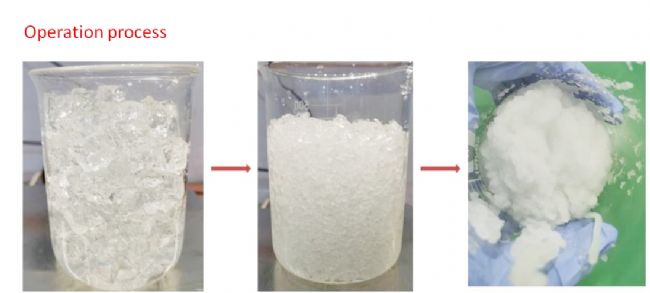

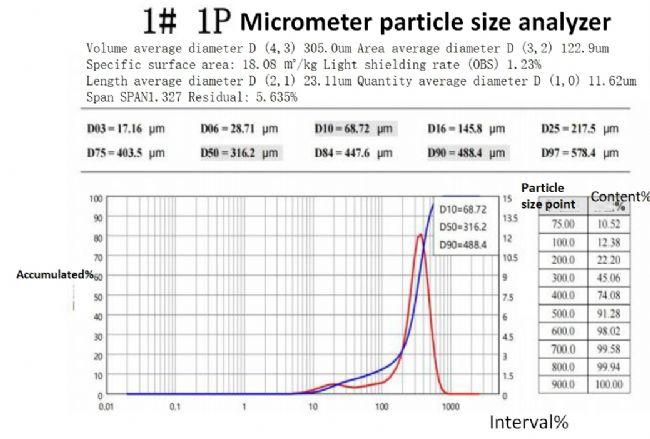

- Gel granulator

| Request Information |

| Other Products |

| Related Products |

| Recently viewed products |