- High pressure microjet homogenizer

- Product Detail

- Company Profile

High pressure microjet homogenizer

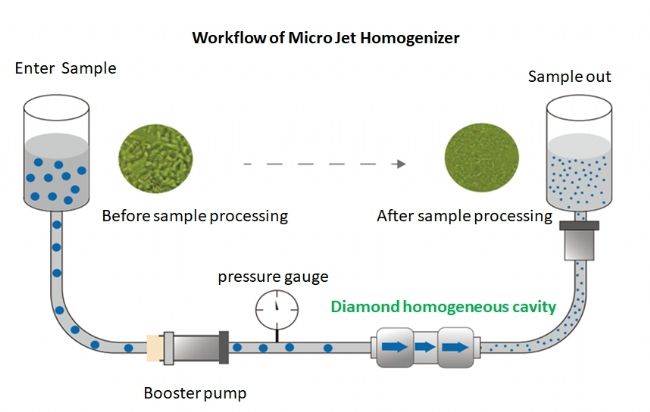

The high-pressure microjet homogenizer is mainly composed of a power unit, a boosting unit, and a homogenization unit.

Under the action of the power unit, the pressurization unit squeezes the fluid material to generate ultra-high pressure, causing the material to pass through the diamond micro hole channel of the homogenization unit at supersonic speed between narrow gaps. During this process, the material is simultaneously subjected to mechanical forces such as high shear, high-frequency oscillation, cavitation, and convective impact, as well as corresponding thermal effects.

These mechanical and physicochemical interactions can cause changes in the physical, chemical, and particle structure of materials. This produces smaller nanoparticle sizes and particle size distributions, achieving homogenization effects.

When the fluid flows through a diamond homogenization chamber with a sudden decrease in aperture, due to the Venturi effect, the pressure sharply decreases and the flow rate sharply increases. The material rubs and collides with the homogenization chamber at supersonic speed. At the same time, due to the sudden decrease in pressure, the fluid material will produce cavitation. Under various mechanical forces and corresponding thermal effects, the particle size and structure of the fluid material will change, achieving the purpose of homogenization and fragmentation.

The equipment adopts a fully diamond homogeneous cavity, and compared to traditional equipment, we provide a better solution:

⚫ Made entirely of diamond material, it has stronger durability and is less prone to wear and tear; Simultaneously capable of withstanding a maximum pressure of 45000psi (approximately 310MPa)

⚫ Not prone to metal particle peeling, resulting in contaminated materials; Aseptic requirements are easier to achieve

⚫ T-shaped self flushing, continuous operation without blockage,

⚫ Adopting a porous groove design, it can achieve linear amplification from experimental small-scale processing to mass production, with excellent reproducibility

⚫ Compared to traditional external cooling devices, it can provide real-time cooling and reduce thermal fatigue

⚫ Realized the design of pore sizes ranging from 50 μ m to 400 μ m, reaching the global advanced level

Application of Micro Jet Homogenizer in the Cosmetics Industry

Liposome coating preparation of ceramide, guaiaculene and other active ingredients, emulsification of lipstick, exosome, compound peptide, nano lotion, collagen, cream, cream, water emulsion, essence and other cosmetics

Application of Micro Jet Homogenizer in Electronic Materials and New Energy Industry

Dispersion of carbon nanotubes, dispersion of battery slurries, exfoliation of graphene, dispersion of various nano oxides, dispersion of platinum carbon catalysts, etc

Application of Micro Jet Homogenizer in the Pharmaceutical Industry

Preparation of nanomedicine carriers, gene delivery, drug microfabrication, preparation of complex injections, and efficacy enhancement

Application of Micro Jet Homogenizer in Fine Chemical Industry

Dispersion of micro nano ceramic slurry, dispersion of ink, synthesis and modification of polymer materials, etc

Application of Micro Jet Homogenizer in Biotechnology Industry

Extraction, separation, and purification of various natural products, peptides, cell lysis, and bioactive substances

Product selection specification table:

| Max working flow rate | Type | Max working pressure | power | Size(Length*Width*Height) | Weight |

| 150mL/min | Lab | 276MPa/40000psi | 3kW | 933x 468*433 mm | 85kg |

| 340mL/min | Pilot | 276MPa/40000psi | 5.5kW | 800*800*1350 mm | 310kg |

| 1L/min | Pilot | 207MPa/30000psi | 18kW | 1200*700*1350 mm | 650kg |

| 2L/min | Pilot | 207MPa/30000psi | 30kW | 2450*1000*1630 mm | 1300kg |

| 4L/min | Process | 207MPa/30000psi | 37kW | 2450*1000*1480 mm | 1800kg |

| 8L/min | Process | 207MPa/30000psi | 75kW | 2500*1250*1840 mm | 2500kg |

| 50-1000L/H | Process | 10000-40000psi(69-276MPa) | 10-75kW |

Application field description:

The main applications of microjet homogenizer in biotechnology are:

1、 Extraction and Separation of Bioactive Substances

Bioactive substance extraction: Micro jet homogenizer can be used to efficiently extract bioactive substances such as proteins, enzymes, nucleic acids, etc. from biological tissues. Through strong shear and impact, the cell wall can be destroyed and active substances inside the cell can be released.

Separation and purification: After extraction, the microjet homogenizer can also assist in the separation and purification process of bioactive substances. By adjusting the homogenization parameters, substances with different molecular weights or properties can be separated.

2、 Biomedical research and diagnosis

Cell fragmentation and molecular release: In cell biology research, microjet homogenizers can be used to break cell membranes and release biomolecules inside cells, such as proteins, nucleic acids, etc., providing high-quality samples for subsequent molecular biology experiments.

Biomarker detection: Homogenization treatment can improve the sensitivity of biomarker detection in biological samples, which is helpful for early diagnosis and treatment monitoring of diseases

3、 Preparation and Modification of Biomaterials

Biomaterial synthesis: Microfluidic homogenizers can be used to synthesize biomaterials with specific structures and functions, such as tissue engineering scaffolds, drug controlled release systems, etc. Through homogenization treatment, the pore size and surface morphology of the material can be controlled to meet different application requirements.

Material modification: For existing biomaterials, microjet homogenizers can also be used for surface modification treatment, by introducing specific functional groups or changing the surface morphology, to improve the biocompatibility and functionality of the material.

In summary, micro jet homogenizers have broad application prospects in the field of biotechnology, and their efficient and accurate homogenization and dispersion capabilities provide strong support for the research and production of biotechnology. With the continuous advancement of technology and the expansion of application fields, the application of microjet homogenizers in the field of biotechnology will become more extensive and in-depth.

The main applications of microjet homogenizer in food are:

The application of microjet homogenizer in the food industry is very extensive, mainly reflected in the following aspects:

1、 Improve food taste and stability

The micro jet homogenizer achieves homogenization of food materials by high-speed injection of small jets, which generate strong shear and impact effects on the raw materials. This processing method helps improve the taste and stability of food. For example, in the production of foods such as ice cream and mayonnaise, micro jet homogenizers can make fat globules smaller and more uniform, thereby improving the delicacy and stability of the product

2、 Improve food quality

Micro jet homogenizers also have important applications in the production of liquid foods such as juice and milk. Through homogenization treatment, large molecular aggregates in food can be destroyed, causing their molecular chains to break, thereby improving the flowability and solubility of food. This helps improve the taste and quality of food, making the product smoother, easier to digest, and absorb.

3、 Extend the shelf life of food

Micro jet homogenizer can destroy the microbial cell structure in food during the homogenization process, thereby achieving bactericidal or bacteriostatic effects. This helps to extend the shelf life of food and improve its safety. Meanwhile, homogenization treatment can also make the nutrients in food more evenly dispersed, improving the bioavailability of nutrients.

4、 Specific application examples

Juice production: In juice production, a micro jet homogenizer can refine the pulp particles and fibers in the juice, making the juice taste more delicate. Meanwhile, homogenization treatment can also break down large molecular substances such as pectin in the juice, improving its stability and transparency.

Dairy processing: In dairy processing, micro jet homogenizers can be used for homogenization treatment of products such as milk and cream. Through homogenization treatment, the fat globules in dairy products can be made smaller and more uniform, thereby improving the taste and stability of the product. In addition, homogenization treatment can also disrupt the microbial cell structure in dairy products and extend their shelf life.

Seasoning manufacturing: In the production of seasonings such as egg yolk sauce, a micro jet homogenizer can evenly mix oil droplets and egg liquid to form a stable emulsion. This processing method helps improve the taste and stability of seasonings, making them more delicious and tasty.

5、 Technical advantages

High efficiency: The micro jet homogenizer can complete the homogenization process in a relatively short time, improving production efficiency.

High uniformity: It can achieve high uniformity dispersion of materials, improve the quality and stability of food.

Gentle treatment: Gentle treatment of heat sensitive materials to avoid thermal damage and preserve the nutritional and flavor substances in food.

Easy to operate: The device is easy to operate, control, and maintain, reducing production and labor costs.

In summary, micro jet homogenizers have broad application prospects and important technical value in the food industry. With the continuous development of the food industry and the advancement of technological innovation, micro jet homogenizers will play an important role in more fields.

The main applications of microjet homogenizer in cosmetics are:

1、 The application advantages of micro jet homogenizer in the cosmetics industry

1. Improve the delicacy of the product

The texture of cosmetics lotion has a direct impact on the feeling and effect of the product. The micro jet homogenizer can crush the particles in the lotion to the micron or nanometer level, making the lotion texture more delicate and smooth, and improving the comfort and ductility of the product. This increase in delicacy not only enhances the appearance appeal of the product, but also provides consumers with a better experience when using it.

2. Enhance the uniformity of component mixing

Cosmetic lotion is usually composed of water phase and oil phase. Using liposome wrapping technology, through the powerful shearing and mixing action of micro jet homogenizer, the water phase and oil phase components can be fully mixed evenly, avoiding lotion stratification, and ensuring the stability and consistency of the product. In addition, this technology can better disperse the active ingredients (such as vitamins, antioxidants, etc.) in cosmetics in solvents, improve the permeability and absorption rate of active ingredients, thereby enhancing the efficacy of the product.

3. Extend the service life of the product

The raw materials in cosmetics are prone to decomposition or oxidation, which reduces the stability and service life of the product. Micro jet homogenization technology effectively prevents particle settling and agglomeration by re dispersing and uniformly suspending particles in the solvent, thereby extending the service life of cosmetic products. This is of great significance for improving the market competitiveness of the product.

4. Meet customized needs

The micro jet homogenizer can obtain cosmetics lotion products with different particle sizes, textures and functions by adjusting processing parameters according to different cosmetics formulations and process requirements. This highly customized capability meets the diverse consumer demands in the market, providing cosmetics companies with more opportunities for product innovation and differentiated competition.

2、 Application examples

In cosmetics production, micro jet homogenizers are commonly used for process steps such as uniform mixing of raw materials, particle crushing, and homogenization treatment.

For example, raw materials containing active ingredients such as ceramide and retinol often have problems such as low absorption rate and poor stability. Using a microfluidic homogenizer to apply liposome encapsulation technology can achieve particle size ≤ 100nm, better permeability, and easier absorption by the skin; Avoiding direct contact between ingredients and skin reduces irritation and other advantages.

After mixing ceramide with phospholipids, surfactants, glycerol, etc. according to the formula ratio, use a DNH-340 microjet homogenizer to homogenize twice. The material changes from a white opaque liquid to a light white transparent liquid.

At the same time, in the preparation of high-end skincare creams, various oils, emulsifiers, active ingredients and other raw materials can be uniformly mixed and refined to the nanometer level through the treatment of micro jet homogenizers, thereby preparing skincare cream products with delicate texture and significant efficacy. In addition, the technology is also widely used in the production of liquid foundation, sunscreen, eye shadow cream and other cosmetics.

3、 Conclusion

Micro jet homogenizer, as an efficient and precise material processing technology, plays an increasingly important role in the cosmetics industry. It has brought significant economic and social benefits to cosmetics companies by improving the delicacy of products, the uniformity of ingredient mixing, extending product service life, and meeting customized needs. With the continuous advancement of technology and the continuous development of the industry, it is believed that micro jet homogenizers will show broader application prospects in the field of cosmetics.The main applications of microjet homogenizer in pharmaceuticals are:

1、 Drug preparation

1. Preparation of nano drug carriers: Micro jet homogenizers can be used to prepare nano drug carriers, such as liposomes, polymer nanoparticles, etc. Through its homogenization and dispersion techniques, it is possible to achieve uniform encapsulation and stability of drugs, thereby improving their bioavailability and efficacy. This is of great significance for improving the therapeutic effect of drugs and reducing side effects.

2. Fine treatment of drugs: Micro jet homogenizer can finely treat drug particles, improving the solubility and bioavailability of drugs. Especially for poorly soluble drugs, nanoscale treatment can significantly increase their solubility, thereby improving the absorption rate of the drug.

2、 Drug delivery

1. Gene Vector Delivery: In gene therapy and cell biology research, microjet homogenizers can effectively deliver gene vectors into cells, achieving the goals of gene therapy and gene expression regulation. This is of great significance for the development of new gene therapy drugs.

2. Preparation of complex injections: The microjet homogenizer performs well in preparing complex injections such as lymphatic vessel injection nanosuspensions, lipid nanoparticles, etc. Through its strong shear and impact effects, injection products with uniform particle size distribution and good stability can be obtained.

3、 Characteristics and advantages

1. Large processing capacity: The production-oriented micro jet homogenizer is suitable for industrial continuous production and can meet the needs of large-scale pharmaceutical production.

2. Narrow particle size distribution range: By precisely controlling the homogenization parameters, products with narrow particle size distribution range and high uniformity can be obtained, which is crucial for improving the stability and efficacy of drugs.

3. Time saving and energy-saving: The micro jet homogenizer can complete homogenization treatment in a short period of time with low energy consumption, which helps to reduce production costs.

4. Meet medical standards: The micro jet homogenizer adopts a fully diamond homogenization chamber, which poses no risk of heavy metal contamination. The material contact surface is usually made of 316L stainless steel material and polished to meet GMP standards, which can meet the strict requirements of the pharmaceutical industry for equipment materials and cleanliness.

4、 Application Cases

In the pharmaceutical industry, micro jet homogenizers have been successfully applied in the preparation process of various drugs. For example, it is used to prepare complex injection products such as propofol emulsion, paclitaxel for injection (albumin bound), lipid microsphere injection, squalane vaccine adjuvant, etc. After being processed by a micro jet homogenizer, these products have a uniform particle size distribution and good stability, receiving unanimous praise from the market.

The main applications of microjet homogenizer in fine chemical industry are:

Micro jet homogenizer plays an important role in the preparation of nanomaterials, homogeneous dispersion of pigments, dyes, inks, homogeneous treatment of high viscosity liquids, and homogeneous mixing of organic mixtures

1、 Preparation of nanomaterials

The microjet homogenizer has significant advantages in the preparation of nanomaterials due to its ability to refine materials to the nanoscale through high-pressure microjet technology. This technology can be used to prepare various nanoscale materials, such as nanoparticles, nanofibers, etc. These nanomaterials have broad application prospects in fine chemicals, new materials, and other fields.

2、 Homogeneous dispersion of pigments, dyes, and inks

In the production process of pigments, dyes, inks and other products, micro jet homogenizers can achieve uniform dispersion of solid particles such as pigments and dyes in liquids, improving the color uniformity and stability of products. By using a micro jet homogenizer, the particles of pigments, dyes, and other materials can be refined, thereby improving the printing effect and coloring power of the product.

3、 Homogenization treatment of high viscosity liquids

For high viscosity liquid products such as lubricants, adhesives, etc., micro jet homogenizers can achieve efficient homogenization treatment. Through the action of high-pressure microjet, the large molecular aggregates in the liquid can be destroyed, the viscosity of the liquid can be reduced, and various components in the liquid can be more evenly dispersed, improving the quality and stability of the product.

4、 Homogeneous mixing of organic mixtures

In the field of fine chemicals, it is often necessary to prepare various organic mixtures. The microjet homogenizer, with its efficient homogenization and mixing ability, can achieve uniform mixing between different organic components, improving the uniformity and stability of the mixture. This is of great significance for the preparation of high-performance organic materials.

5、 Technical advantages

Efficient homogenization: The micro jet homogenizer can achieve uniform dispersion and refinement of materials in a short period of time, improving production efficiency.

Particle size control: By adjusting the parameters of the homogenizer, the particle size distribution of the product can be precisely controlled to meet the needs of different fields.

• Gentle treatment: Gently treat thermosensitive materials to avoid thermal damage and preserve their activity and stability.

Easy to operate and maintain: The equipment is easy to operate, control, and maintain, reducing production and labor costs.

In summary, micro jet homogenizers are widely used in the fine chemical industry, and their unique homogenization technology and efficient and stable performance provide strong support for the production and research and development of fine chemical products. With the continuous advancement of technology and the expansion of application fields, the role of microjet homogenizers in the fine chemical industry will become even more important.The main applications of microjet homogenizer in materials are:

1、 Working principle of microjet homogenizer

The microjet homogenizer utilizes the intense shear force and cavitation effect generated when high-pressure fluid passes through a specially designed microporous structure, which accelerates the material to supersonic speed in an instant, thereby achieving homogenization and dispersion of the material. During the homogenization process, materials are subjected to strong impacts, shearing, and cavitation, causing internal dispersion of aggregates and ultimately resulting in uniform particles at the nanometer or micrometer level. This technology not only improves the dispersion effect of materials, but also maintains the chemical and physical stability of materials.

2、 Application of Micro Jet Homogenizer in Electronic Material Processing

1. Preparation of Nanoelectronic Materials

Nanoelectronic materials have a wide range of applications in semiconductor, display technology, sensors, and other fields due to their unique electrical, optical, and magnetic properties. The microjet homogenizer can prepare uniformly sized and well dispersed nanoparticles, such as quantum dots and metal nanoparticles, by precisely controlling the pressure and flow rate of the fluid. These nanoparticles can significantly enhance the performance and stability of electronic devices.

2. Homogenization of electronic paste

Electronic paste is an indispensable material in electronic manufacturing, widely used in fields such as printed circuit boards and solar panels. The micro jet homogenizer can uniformly disperse solid particles in electronic slurries in solvents, improving the flowability and printing accuracy of the slurries. Meanwhile, homogenization treatment can also reduce particle agglomeration, improve the stability and service life of the slurry.

3. Modification of electronic packaging materials

Electronic packaging materials are crucial for the reliability of electronic products. By using a microjet homogenizer to modify packaging materials, the mechanical properties, thermal stability, and electrical insulation performance of the materials can be significantly improved. For example, uniformly dispersing nano fillers in packaging resins can significantly improve the rigidity and heat resistance of packaging materials, and extend the service life of electronic products.

4. Preparation of composite materials

In the field of electronic materials, composite materials have received widespread attention due to their excellent comprehensive properties. The micro jet homogenizer can uniformly disperse different types of nano or micro particles in the matrix material, and prepare high-performance composite materials. These composite materials have broad application prospects in electronic packaging, electromagnetic shielding, thermal management, and other fields.

3、 Experimental case

Use a pilot micro jet homogenizer to process graphene materials.

Original solution (left) and processed solution (right)

Before processing, the sample is viscous and has good fluidity; After processing, the sample appeared jelly like with decreased fluidity. The particle size before and after processing was tested using a laser particle size analyzer, and the results are shown in the figure:

4、 Advantages of Nanojet Homogenizer

1. Efficiency: The micro jet homogenizer can achieve a maximum flow rate of 480L/h at 40000psi, which can complete the homogenization process in a short time and significantly improve production efficiency.

2. Accuracy: By precisely controlling operating parameters, precise control of material particle size and dispersion can be achieved.

3. Gentle treatment: The DNH series micro jet homogenizer can be equipped with a water cooling system to gently treat heat sensitive materials, avoiding thermal damage and maintaining the chemical and physical stability of the materials.

4. Wide applicability: Suitable for processing various electronic materials, including nanoparticles, electronic pastes, packaging materials, and composite materials.

5、 Conclusion

Micro jet homogenizers have shown great potential in the field of electronic material processing due to their efficient and precise homogenization and dispersion capabilities. Through microjet technology, nano electronic materials with uniform size and good dispersion can be prepared, improving the flowability and printing accuracy of electronic pastes, enhancing the performance of packaging materials, and producing high-performance composite materials.

consulting service:pangjun@costones.com

-

Suzhou COSTONES Instruments Co., Ltd. (COSTONES) is an instrument company focusing

on separation and purification. It is an equipment supplier and service provider

for biopharmaceutical, cell therapy and gene testing. It is committed to providing

users with industry-leading technical support and services.

The company has a perfect service system and executive power. It interprets the

user experience from the four aspects of technical communication, scheme design,

technical support and after-sales service, and tries to achieve seamless connection

in every link until it is recognized by customers.

For a long time, we have maintained good cooperative relations with domestic and

foreign suppliers. The main products include protein purification system,

compressible chromatographic column, ultrafiltration system, chromatographic

ultrafiltration accessories, etc., and provide maintenance services and customized

product services;

At present, Suzhou quarrying has provided high-quality services for

biopharmaceutical, cell therapy, research institutes and scientific research users.

It has carried out in-depth cooperation with customers and become a reliable partner

for customers to achieve win-win results.

We take quality first as the standard, quickly respond to customer needs, help

customers solve problems, improve efficiency, and take improving core

competitiveness for customers as our service tenet. We are willing to realize our

own value while creating value for customers and society through our unremitting

efforts.

| Request Information |

| Other Products |

| Related Products |

| Recently viewed products |

- SiteMap