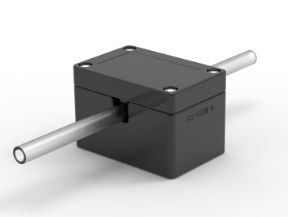

XY-TEK's CS series ultrasonic clamp-on flow sensors are compact in size, and can measure flow and output results without external circuitry. The sensors can be clamped on rigid plastic tubing, such as PFA, PTFE, Teflon, PVDF, PP and Nylon tubing, to accurately measure the liquid flow rate and detect air bubbles. A silicone or rubber layer is used as the acoustic coupling layer between the sensor and tubing. The sensors are not in direct contact with the liquid in the tubing and will not contaminate the liquid. They are especially suitable for applications where strict hygiene is required, such as bio-pharmaceutical processes and medical equipment. The sensor uses the ultrasonic transit-time difference method to non-invasively measure the liquid flow rate in the tubing. It has high precision and stability, can be used repeatedly without disinfection, and does not bring the risk of cross contamination to the liquid. Standard products are available in a range of sizes to match the common tubing outer diameter. The sensors can also be configured as flow switch, bubble detection or dosing control devices.

Common applications in the field of biopharmaceuticals :

CS series sensors are suitable for various biopharmaceutical processes and equipment : Typical application processes include : medium and buffer preparation, filtration, acid and alkali supply, inoculation, fermentation, harvest, chromatographic analysis, perfusion clarification, purification, filling, etc. Common applicable equipment includes : disposable reaction containers, fermentation tanks, cell culture equipment, vaccine production, tangential flow filtration system, liquid chromatograph, chromatography, etc.

Common applications in other areas :

Medical devices such as hemodialysis machines, artificial hearts, organ transplant systems, blood pumps

Scientific Experiment System

Water and wastewater treatment systems

Food, beverage processing, such as milk, juice, beer production process

Filling equipment, spraying equipment, cooling system, lubrication system

Fluid monitoring during semiconductor manufacturing processes, such as high-purity water, high-purity chemical reagent transfer lines

Some technical features of the sensor include :

High precision and high stability

Non-invasive measurement, no direct contact with liquid, hygienic safety

Two-way measurement, calculation of fluid volume, both bubble detection, quantitative filling, flow switch function

The circuit is integrated inside the sensor / flowmeter without external calculation and processing system, and the size is compact.

No blockage, no steering and no dead angle, the fluid pressure loss is small.

Provide standard output mode and customer system seamless integration

The material, size, temperature and liquid type of plastic hard tube can be specified for customized calibration.

Xunyin has a series of standard size products, which are suitable for common pipeline sizes. The outer diameters of the pipes supported by the standard size products are :

1 / 4 ' ( 6.4mm )

5 / 16' ( 7.9mm )

3 / 8 ' ( 9.5mm )

1 / 2' ( 12.7mm )

5 / 8 ' ( 15.9mm )

3 / 4 ' ( 19.1mm )

1 ' ( 25.4mm )

In addition to standard size products, we can also customize for the special requirements of users. The sensor can be configured with flow switch, bubble detection and filling function.

Some specification parameters :

Accuracy : 2 % with zero drift

Measurable liquids : water, blood, beverages, gasoline, paint, etc., do not contain or contain less solid particles

Liquid temperature : 0 ° C ~ 60 ° C

Calibration : manufacturer default calibration : 22 ± 3 ° C, water

Storage temperature : -20 ° C to 70 ° C

Suitable for pipes : PFA, PTFE, Teflon, PP, PVDF, Nylon and other hard pipes with smooth inner and outer surfaces

The maximum flow range of standard model products : depending on the diameter of the specific standard model, between 6000 ~ 24000 mL / min

Shell material : plastic

Accessories : 8-core shielded cable, default length 1.5 m

Optional accessories :

1.USB data converter, a sensor can be connected to the computer.

2.Flow sensor tool box with display, allowing up to 3 sensors to be connected to the computer at the same time.

3.flow sensor display screen, connect a sensor, and the sensor cable adapter leads.

4.Data cable, 3 meters, push-pull plugs at both ends, connected to the flow display and sensors.

In addition to CS series sensors, Xunyin Technology also provides a variety of ultrasonic flow sensors and equipment. If you have any questions, please contact our 021 33885752, info @ xy-tek.cn or visit our official website www.xy-tek.cn for more details.

bio-equip.cn