60L sterile water tank for lab water purification system

Ultrapure water will be contaminated even if it is slightly exposed to the external environment.Therefore, it is recommended to use sterile water tanks to store ultrapure water to prevent changes in water quality.

When glassware in the laboratory holds ultrapure water,Glass will dissolve a large number of ions,This will change the resistivity value of the ultrapure water.

Therefore, Sichuan Zhuoyue Water Treatment Equipment Co., Ltd. used different levels of high-density polyethylene and polypropylene to conduct experiments to test the dissolution of these materials when selecting materials for the sterile water tank storage system.

Place 5mg of different raw materials in 100mL of ultrapure water.(Resistivity 18.2MΩ.cm, TOC< 10ppb),The dissolution was tested after 24 hours and it was found that there was not much difference in the dissolution of ions among several compared materials.

But measure again after 3 days,It was found that the dissolved Cl, NO3, SO3, and Mg from polypropylene were higher than those from polyethylene(Refer to R&D 001).In terms of organic matter (measured as TOC ppb), the TOC content dissolved from polyethylene has been decreasing over the past 3 days.

This shows that as long as it is cleaned carefully, it is possible to achieve minimal dissolution of organic matter from the PE water tank.

Compared with other materials, such as FEP (fluorinated ethylene propylene), PFA, PTFE (polytetrafluoroethylene), PA (polyamide), PU (polyurethane), PE materials have very little ion and organic matter dissolution.

Therefore, our company chooses food-grade PE material as the material of ultrapure water storage Strile Water Tank.

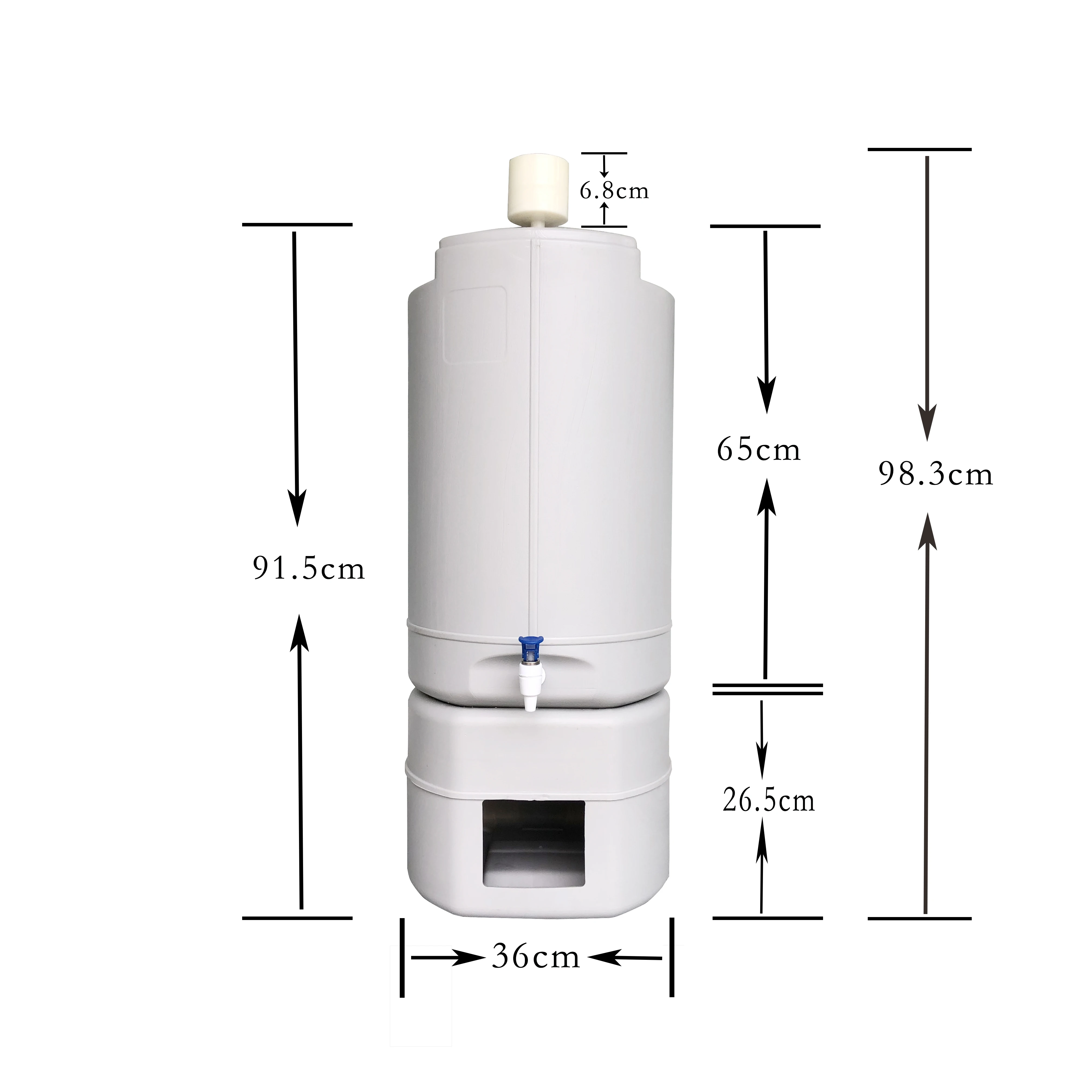

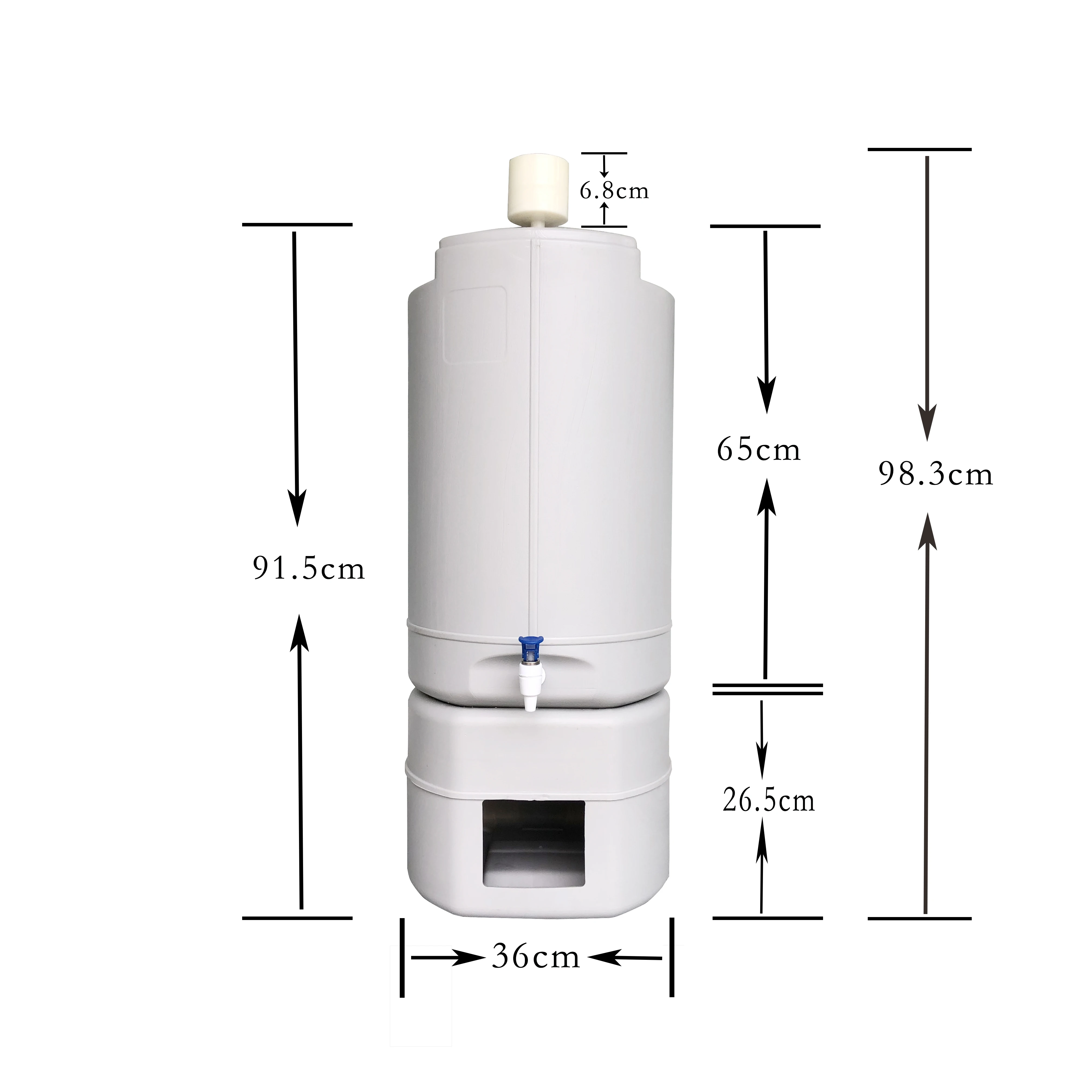

Dimensions of 60L sterile water tank:

total height 91.5cm (base height 26.5cm, water tank height 65cm)

base diameter about 36cm,

respirator height: 6.8cm.

| Material |

Polyethylene material |

| Technology |

blow molding process |

|

Capacity

|

60L |

Feature of 60L sterile water tank for lab water purification system :

1.Made of polyethylene material and blow molding process, no adhesives or surfactants are used in the manufacturing process.

2.The sealed and oversized water tank cover prevents air from entering the water tank and facilitates manual cleaning; the polyethylene material greatly avoids the dissociation of small molecules.

3.The internal surface of the water tank is smooth, making it difficult for biofilm to grow; the cylindrical shape reduces the internal surface area of the barrel, thereby reducing contact with pure water.

4. Water enters from the bottom of the barrel to ensure minimal carbon dioxide absorption, and the conical bottom of the barrel can be completely drained to ensure thorough cleaning (a drain valve is set at the bottom).

5. Use with optional accessories: the air filter can absorb CO2 and organic matter, filter bacteria, particulate matter, etc.; the ultraviolet lamp can control microorganisms and reduce organic matter (TOC) content.

bio-equip.cn