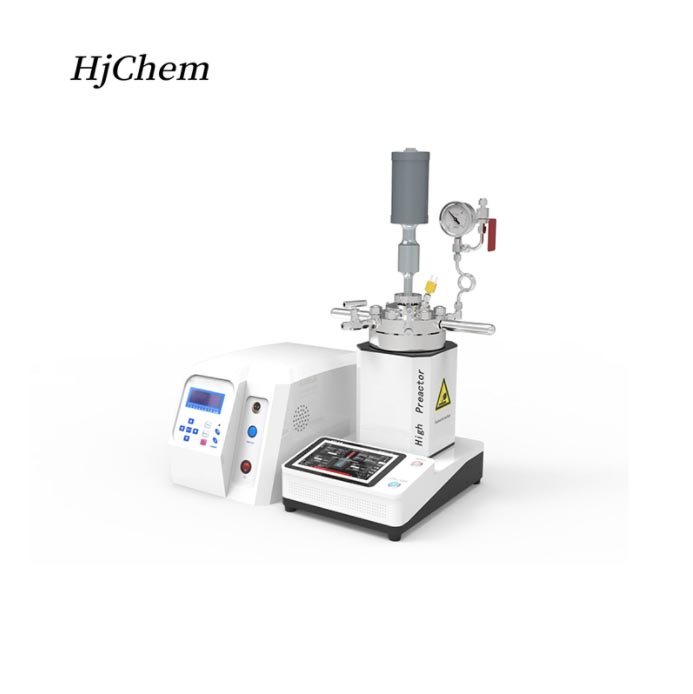

Introducing the breakthrough Laboratory Ultrasonic High Pressure Autoclave Batch Reactor, this isn’t just another high pressure batch reactor.

It’s a purpose-built high pressure autoclave reactor designed for exceptional containment and safety (meeting stringent autoclave standards), handling aggressive chemistries and volatile reactions with confidence.

Basic Technical Specifications:

1. Volume: 100/250/500/1000ml (customizable)

2. Material: 316L (other special materials customizable)

3. Structure: Flange type

4. Heating method: electrical heating.

5. Temperature: RT-300°C (customizable)

6. Pressure: -0.1-10MPa (customizable)

7. Agitation Method: magnetic stirring, speed max 1500RPM.

8. Interfaces on the lid (7 openings): temperature sensor, pressure gauge & rupture disc, gas inlet, vent, ultrasonic port, spare ports *2pcs

9. Power Supply: AC220V, 50HZ/60HZ

10. Control: Touch screen control, PID self-tuning temperature control.

Integrated Ultrasonic Power

The defining feature is its integrated Ultrasonic High Pressure Reactor capability. Directly coupled high-intensity ultrasonic probes deliver powerful, controllable cavitation energy inside the pressurized reaction vessel.This enables:

1. Radically Enhanced Mixing & Mass Transfer: Eliminate diffusion limitations even in viscous media or multiphase systems.

2. Accelerated Reaction Kinetics: Ultrasonic energy provides activation energy, significantly speeding up reaction times for synthesis, catalysis, and decomposition.

3. Superior Particle Size Reduction & Dispersion: Achieve nano-scale particles and unparalleled dispersion stability crucial for catalysts, nanomaterials, and composites.

4. Improved Nucleation & Crystallization: Gain precise control over crystal size and morphology.

5. Efficient Cell Disruption & Extraction: Powerful for bio-based applications under pressure.

For more information, please visit us:

https://njhjchem.com/product/high-pressure-reactors/laboratory-ultrasonic-high-pressure-autoclave-batch-reactor/

bio-equip.cn