Crystal CellRoller® is designed for the production of monolayer and suspension cell cultures. All Crystal CellRoller® units have digital control systems and stable mechanical structure. A full range of speed settings and rotation modes come as standard features providing consistent optimal media distribution, gas exchange and maximum surface area for cell growth. Crystal CellRoller® systems are the ideal choice for both research and industrial needs.

Working Table for Customized Order for Roller Culture Apparatus

| Bottle DiameterΦ(mm) |

Bottle Length(mm) |

Bottle Positions per Deck M |

Decks N |

Bottle Speed Selection |

Width W(mm) |

Depth D(mm) |

Height H(mm) |

Voltage(V) |

| |

|

|

|

Please check required speed

□ 3-60 r/h for Monolayer Cell Culture

□ 60-900 r/h for Suspension Cell Culture

□ 1-999r/h for both Monolayer and Suspension Cell Culture |

|

|

|

|

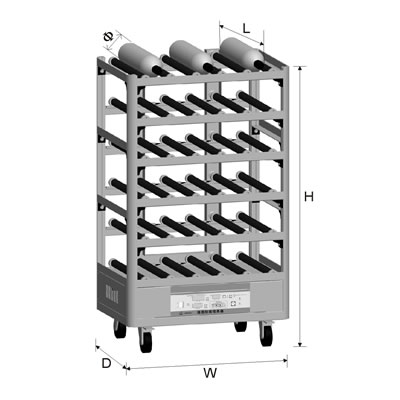

Formula for Calculate W, D and H

1. For total bottle positions≤8,control box is external.

Please check the bottle size first.

W=102+1.1Φ×M(mm)

D=L+98(mm)

H=250+1.7Φ(N-1)(mm)

2. For total bottle positions>8,control box is external.

Please check the bottle size first.

W=172+1.1Φ×M(mm)

D=L+112(mm)

H=380+1.6Φ(N-1)(mm)

Notes

1. If the customized Roller Apparatus is to be used in incubator, please make sure W, H and D are within the incubator's interior dimensions.

2. If the customized Roller Apparatus is not used in the incubator, please check the Roller Apparatus' outside dimensions(W, H and D) to ensure it can fit into your room facility and dimensions such as the door, ceiling height.