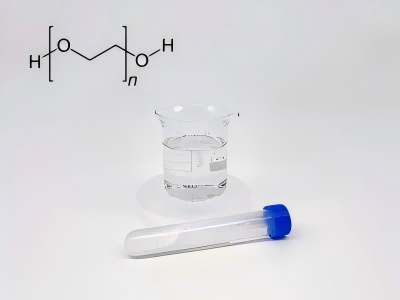

Chemical name: Polyethylene Glycol

INCI Name: Polyethylene Glycol

CAS Registry Number: 25322-68-3

EINECS login ID: 500-038-2

HS Code: 3907210000

Molecular formula: (C₂H₄O)n

Molecular weight: 600

Synonyms:Polyethyleneoxide,Macrogol,Carbowax,Carbowax Sentry,Lipoxol, Lutrol E,Macrogola, PEG, Pluriol E, polyoxyethylene glycol, PEG600,Macrogol 600

Application Areas

1. Food Industry: Polyethylene glycol 600 is commonly used as an emulsifier, thickener, anti-crystallization agent, stabilizer, and humectant. It can improve the viscosity and stability of food, and enhance its taste, texture, and appearance. In baked goods, it prevents ice crystal formation and extends freshness; in sauces, condiments, and gravy, it acts as a thickener and preservative, giving products a smooth, creamy texture while inhibiting the growth of bacteria and fungi.

2. Beverage industry: It can be used as an antifoaming agent in the production process of beer and soft drinks to effectively solve the problem of excessive foam and ensure the stability of product appearance and quality.

3. Manufacturing: Polyethylene glycol 600 can be used as a coolant, antifreeze, additive, diluent or surface treatment agent to lower the freezing point of liquids and prevent the cooling system from freezing. It is commonly used in the automotive, industrial equipment, air conditioning systems, lubricating oil, coatings, paints, pulp and textile industries to ensure normal liquid flow in low-temperature environments and improve product processing performance.

4. Pharmaceutical manufacturing: As a solvent, diluent, and carrier for drug delivery systems, it can be used in the preparation of various pharmaceuticals and medical products.

5. Daily chemical industry: Used as a wetting agent and consistency regulator, widely used in products such as creams, lotions, toothpaste, shaving cream and detergents; also suitable for leave-in hair care products, giving hair smooth and shiny.

6. Coatings Industry: Polyethylene glycol 600 has wide applications in the coatings industry. It can participate in the curing of epoxy resins, improve coating flexibility, impact strength, and adhesion, and reduce shrinkage. It can also disperse pigment particles, adjust system viscosity, optimize coating leveling and gloss, and enhance coating freeze resistance, ensuring application and performance in low-temperature environments.

bio-equip.cn