| Product Overview |

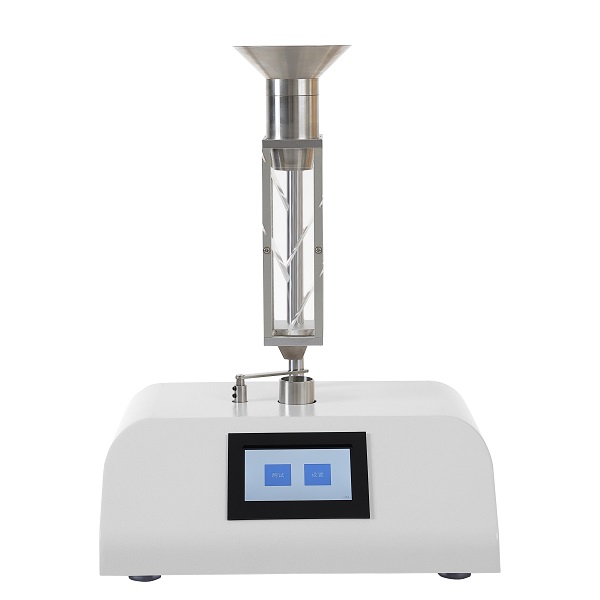

The Scott Volumeter is an intelligent apparatus for measuring apparent density. It features an advanced touchscreen interface and a single-station testing design, enabling precise measurement of the apparent density of powder materials. It is widely used for density testing of powders in industries such as pharmaceutical, chemical, food, and building materials. |

| Application Fields |

Pharmaceutical industry: Density testing of powdered medicines to ensure product quality

Chemical industry: Density measurement of chemical raw materials

Food industry: Density testing of food additives

Building materials industry: Density testing of construction materials such as cement and mortar

Research institutions: Density testing in material science research |

| Technical Specifications |

Hardware

Specifications |

Main Control System |

CPU Frequency: 240MHz (Dual-Core) |

| Flash Storage: 8MB |

| PSRAM: 8MB |

| Operating System: FreeRTOS |

| Operating Voltage: AC110/220V,50/60Hz |

| Power Consumption: < 15W |

| Display System |

Display Screen: 4.3-inch TFT Color Liquid Crystal Display |

| Resolution: 800×480 pixels |

| Color Depth: 16-bit High Color |

| Touch Panel: Capacitive Type |

| Measurement System |

Load Cell: High-Precision Load Cell |

| Measurement Accuracy: 0.01g |

| Measuring Range: 0-300 g |

Communication

Interface |

Communication Protocol: RS485 Modbus RTU |

Software

Functional

Specifications |

Measurement Function |

Bulk Density Measurement: Measures the density of powder materials under natural accumulation conditions. |

| Calibration Function |

Zero Calibration: Automatic or manual zero point calibration |

| Weight Calibration: Uses standard weights for weight calibration |

| Weight Calibration: Uses standard weights for weight calibration |

| User Interface Features |

*Step-by-Step Wizard: 5-step guided measurement process* |

| Localized Interface: Complete English language support |

| On-screen Keypad: Numeric and decimal point input capability |

| Live Data Display: Real-time measurement values with status indicators |

| Profile Management: Save/load configuration profiles |

Operational

Process |

Test Sequence |

a. Tare Measurement: Weigh empty container or manually input tare mass |

| b. Guidance Prompt: Display step-by-step operational guidance |

| c. *Blade Configuration: Set leveling blade speed (e.g. 10mm/s) and traversal direction* |

| d. Gross Measurement: Weigh filled container or input total mass |

| e. Auto-Calculation: System computes bulk density (ρ = m/V) with digital display |

| f. Report Generation: Print test report with timestamp and parameters |

| Calibration Process |

a. Enter calibration mode |

| b. Perform zero calibration |

| c. Place standard weights |

| d. Execute weight calibration |

| e. Verify calibration results |

Data

Management |

Configuration

Storage |

Storage method: Custom file system |

| Stored content: Device parameters, test parameters, user settings |

| Backup function: Supports configuration file backup and restoration |

| Test Report |

Report format: Automatically generates standard test reports |

| Print output: Built-in thermal printer |

| Report content: Test data, calculation results, device information |

Safety

and Reliability |

Safety Features |

Electrical safety: Complies with relevant electrical safety standards |

| Data protection: Configuration data protected by CRC verification |

| Fault detection: Real-time device status monitoring |

| Error handling: Comprehensive error detection and recovery mechanisms |

| Reliability |

Hardware reliability: Industrial-grade components, MTBF > 10,000 hours |

| Software reliability: Watchdog protection, automatic recovery from exceptions |

| Environmental adaptability: Operating temperature 0-40°C, humidity <85% RH |

| Maintainability: Modular design for easy maintenance and upgrades |

Technical

Advantage |

Measurement Accuracy |

High-precision weighing: 0.01 g accuracy, meets precision measurement requirements |

| Automatic calculation: Eliminates manual calculation errors |

| Ease of Operation |

Touch operation: Intuitive touchscreen interface |

| Guided workflows: Simplified procedures to reduce operational complexity |

| English interface: Full English display support for domestic and international users |

| System Integration |

Unified communication: RS485 bus for centralized management of multiple devices |

| Modular design: Facilitates functional expansion and maintenance |

| Standardized protocol: Uses standard Modbus protocol for easy integration |