Multi Channel Valves

Multi channel valve refers to an industrialvalve that connects and controls multiple pipelines through a rotating valvecore, with two or more channels. It enables the connection and closure ofdifferent pipeline flow paths. Its core structure includes a valve body, arotating component, and a fluid channel system. In fluid transportation, itsaves space and significantly reduces residual media in the fluid system.

Product advantages

Customized design based on user needs

A very compact valve solution

• Can integrate other components, such as sensor systems

Due to fewer connection points, the safetyof the process has been improved

Pharmaceutical&Personal Care

Application Area

Pharmaceutical&Personal Care/Bio-Fermentation/Pharmaceutical /Chemical/Personal care/Life Science

Food&Beverage/Fluid Food/Food Additives/Drinks/Dairy/Winesxk /Water

Advanced electronic equipment&vacuum applications

Semiconductor and Flat Panel Display Devices(SEMI&FPD)

Solar cells

Industrial Coating

Ultra High Vacuum Scientific Instruments (UHV R&DEquipment)

SemiconductorIndustry&Electronic Engineering

Ultra PureGas Pipeline System UHP Piping System

FactoryEngineering SP1/SP2 (Hook Up)

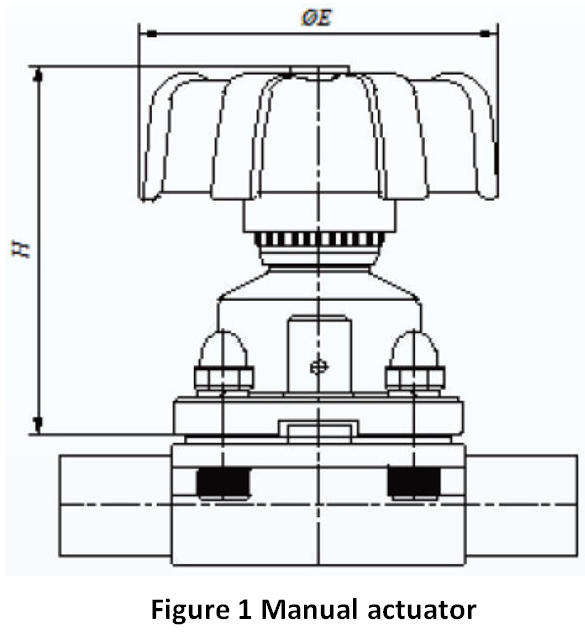

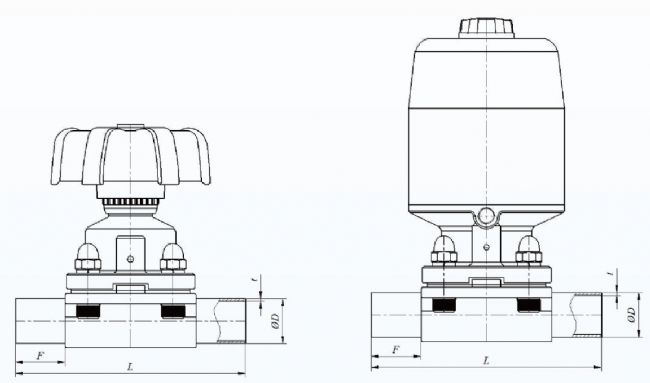

1. Plastichandwheel manual actuator

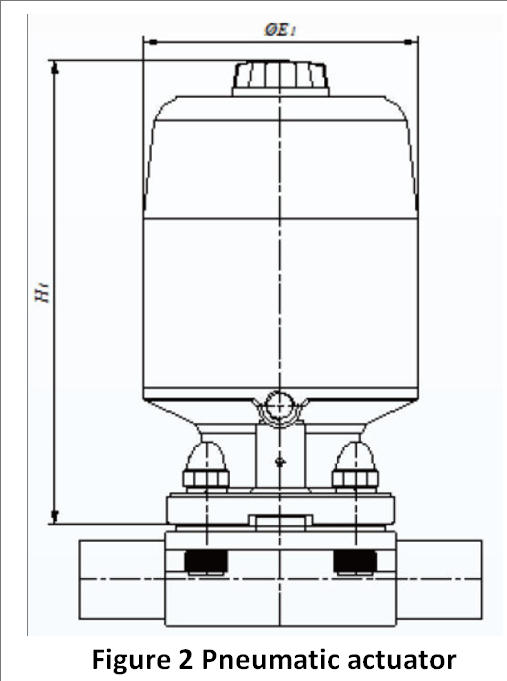

2.Stainless steel pneumatic actuator

Manual and Pneumatic actuators size(mm)

| Type(DN) |

φE |

H |

φE1 |

H1 |

| DN6-15 |

φ35 |

62 |

φ50 |

96 |

| DN15-20 |

φ65 |

83 |

φ75 |

136 |

| DN20-25 |

φ90 |

106 |

φ88 |

150 |

| DN32-45 |

φ110 |

125 |

φ100 |

178 |

| DN50-57 |

φ125 |

148 |

φ112 |

225 |

| DN65-80 |

φ145 |

186 |

φ138 |

306 |

| DN89 |

φ180 |

205 |

φ200 |

354 |

| DN100 |

φ180 |

256 |

φ250 |

395 |

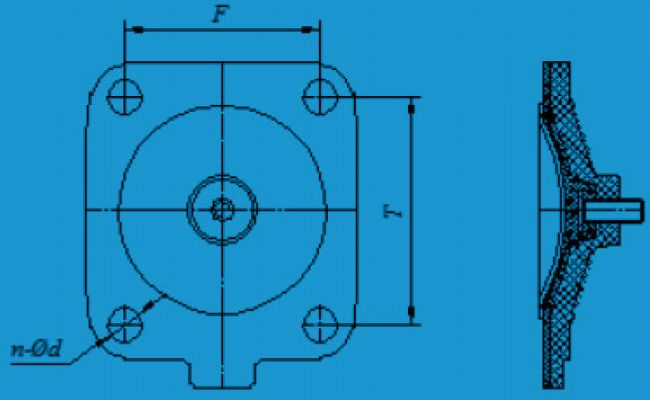

Diaphragm Plates Introduction

Thenew type of diaphragm has added a sealing step compared to the traditionaldiaphragm,

and at the same time, it cooperates with the protrusion on the valvebody to form a closed

annular structure, which not only ensures the reliabilityof the seal, but also reduces the

retention of the medium, thus achieving thesterile requirements of the diaphragm valve.

Thediaphragm has single-layer and double-layer dense structure. The single-layerdiaphragm is composed of artificially synthesized soft rubber EPDM material,with a

reinforced mesh in the middle. The medium contact layer of thedouble-layer diaphragm is made of synthetic plastic PTFE hardcorrosion-resistant material, which is used in conjunction with the soft rubberEPDM layer with

reinforced mesh. Depending on the properties of the medium andthe requirements

of the operating conditions, single-layer or double-layerdiaphragm sheets can be

selected for use.

Diaphragmparameters

Diaphragmselection specification parameters

| TYPE(DN) |

F×T |

n-Ød |

Material |

Max.working pressure |

Steam |

| DN6-15 |

22×22 |

4-Ø4 |

EPDM |

Max.6bar |

Max.130℃ |

| DN15-20 |

35×37 |

4-Ø7 |

| DN20-25 |

48×56 |

4-Ø9 |

| DN32-45 |

65×70 |

4-Ø11 |

| DN50-57 |

75×84 |

4-Ø13 |

PTFE/EPDM |

Max.6bar |

Max.150℃ |

| DN65-80 |

95×106 |

4-Ø18 |

| DN89 |

97×126 |

4-Ø18 |

| DN100 |

φ194 |

8-Ø14 |

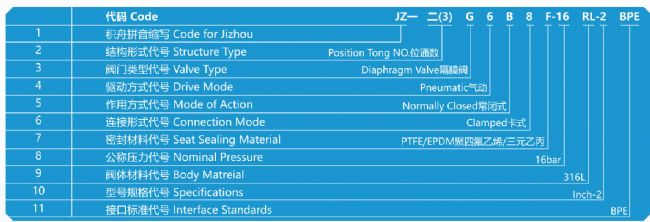

Multi Channel Valves model description

Remark

2 Structural forms: (1) One bit2-way one (2), one bit 3-way one (3), two bit 3-way two (3),

two bit 4-way two(4),

Two digit 5-way two (5), threedigit 3-way three (3), three digit 4-way three (4),

three digit 5-way three(5)... n digit n-way m (n)

4 driving modes: manual (none),pneumatic (6), electric (9)

5 modes of action: double acting(none), normally closed (B), normally open (K)

6 Connection methods: flange (4),welding type (6), card type (8)

Valve body material 316L (RL),titanium alloy (Ti), Hastelloy (Hs)

11 φ12.7(0.5") ,φ19.05(0.75") ,φ25.4 (1") ,φ31.8(1.25"),φ38.1(1.5"),

φ50.8(2"),φ63.5(2.5"),φ76.2(3"),φ101.6(4")

Descriptionof roughness

Surfacetreatment technology

Accordingto the polishing grade requirements of MP or EP surface treatment technology,the

internal and external polishing roughness of Jizhou Company's seriesproducts can meet the

requirements of ASME BPE standard

Theinner surface polishing roughness is divided into MP grade (mechanicalpolishing)

Ra ≤ 0.51 µ m; EP grade (mechanical polishing&electrolyticpolishing) Ra ≤ 0.38 µ m;

and the outer surface polishingroughness is MP grade (mechanical polishing)

Ra ≤ 0.76µ m or Ra ≤ 0.64 µ m.

| |

Inner surface |

Outer surface |

ASME BPE

Surface grade treatment |

polish process |

Ra.Max |

polish process |

Ra.Max |

| uim |

um |

uim |

um |

| SF1 |

Mechanical polishing (MP) |

20 |

0.51 |

Mechanical polishing (MP) |

30 |

0.76 |

Valveparameter table

(1)Directvalve parameters

(1)Manual and Pneumatic Straight Through Valves Size Table

| Type(DN) |

L |

φD*t(3A) |

φD*t(GB) |

F |

| DN15 |

89 |

φ12.7*1.65 |

φ12.7*1.5 |

27 |

| DN20 |

117 |

φ19.05*1.65 |

φ19.05*1.5 |

28 |

| DN25 |

127 |

φ25.4*1.65 |

φ25.4*1.5 |

28 |

| DN32 |

159 |

φ31.8*1.65 |

φ31.8*1.5 |

31 |

| DN40 |

159 |

φ38.1*1.65 |

φ38.1*1.5 |

31 |

| DN45 |

159 |

φ45.0*1.65 |

φ45.0*1.5 |

31 |

| DN50 |

190 |

φ50.8*1.65 |

φ50.8*1.5 |

37 |

| DN57 |

190 |

φ57.0*1.65 |

φ57.0*2.0 |

37 |

| DN65 |

216 |

φ63.5*1.65 |

φ63.5*2.0 |

38 |

| DN80 |

254 |

φ76.2*1.65 |

φ76.2*2.0 |

40 |

| DN89 |

254 |

φ88.9*2.11 |

φ88.9*2.0 |

40 |

| DN100 |

305 |

φ101.6*2.11 |

φ101.6*2.0 |

45 |

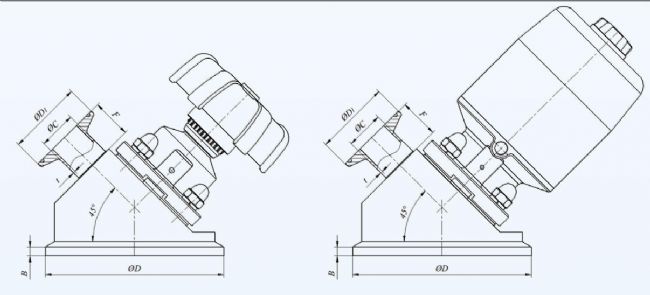

(2)Tankbottom valve parameters table

(2)Tank bottom valve parameters table

| Type(DN) |

φ |

B |

φC*t(3A) |

F |

| DN20 |

φ85 |

6 |

φ19.05*1.65 |

28 |

| DN25 |

φ120 |

6 |

φ25.4*1.65 |

28 |

| DN32 |

φ160 |

6 |

φ31.8*1.65 |

28 |

| DN40 |

φ160 |

6 |

φ38.1*1.65 |

28 |

| DN45 |

φ160 |

6 |

φ45.0*1.65 |

28 |

| DN50 |

φ180 |

6 |

φ50.8*1.65 |

28 |

| DN57 |

φ180 |

6 |

φ57.0*1.65 |

28 |

| DN65 |

φ200 |

6 |

φ63.5*1.65 |

28 |

| DN80 |

φ250 |

8 |

φ76.2*1.65 |

28 |

| DN89 |

φ250 |

8 |

φ88.9*2.11 |

28 |

| DN100 |

φ320 |

10 |

φ101.6*2.11 |

28 |

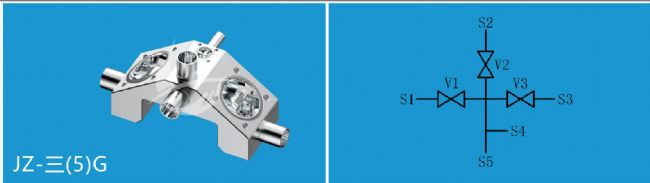

(3)MultipleChannel Valves

Multichannel valve product pictures and schematic diagrams

Engineering case

If you are interested, please feel free to call us for consultation.

Email: pangjun@costones.combio-equip.cn