Home > News > Simplifying Beam Diagnostics with a Laser Beam Reducer

Simplifying Beam Diagnostics with a Laser Beam Reducer

- Optical Surfaces Ltd is a leading supplier of modular and standalone reflective beam reducers to laser facilities looking to perform accurate diagnostics and precise measurements on their beamlines.

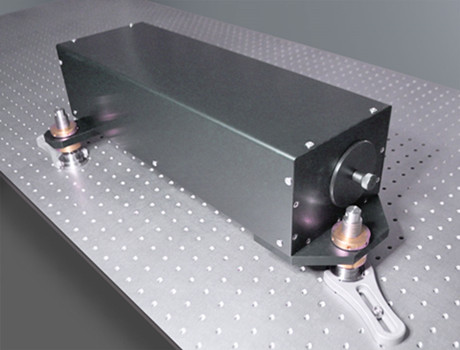

A reflective beam reducer is a device that uses mirrors to reduce the diameter of a collimated laser beam. Unlike transmissive beam reducers that use lenses, reflective laser beam reducers from Optical Surfaces Ltd offer advantages such as high transmission, no chromatic aberration, and the ability to handle broadband sources. They are particularly well-suited for high-power laser applications as there is no internal focus to cause damage.

A1-Series Reflective Beam Reducer mounted on an optical table (courtesy: Optical Surfaces Ltd.)

Traditionally beam reducers have come as complete, pre-aligned mounted optical systems in an enclosure. While this approach provides a good beam reduction solution for optics up to 200mm diameter, above this an enclosed system solution becomes too large, too heavy, and too expensive. For laser facilities producing a collimated beam (up to 500mm diameter) - Optical Surfaces Ltd has developed a new modular approach enabling simple set-up of a larger diameter beam reducer assembly aligned to your optical experiment.

Laser beam reducers (up to 30x) from Optical Surfaces Ltd are based upon high precision off-axis mirrors which provide an unobstructed output and highly efficient transmission. The reflective design of these beam reducers is achromatic and with aluminium coatings can operate from UV to far IR without adjustment.

To discuss a modular or standalone reflective laser beam reducer optimized for your laser experiments please contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com.

Optical Surfaces Ltd has been producing high precision optical components and systems for more than 60 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant, and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable.

-----------

Worldwide HQ

Optical Surfaces Ltd.

Godstone Road

Kenley

Surrey CR8 5AA

UK

Tel. +44-208-668-6126

email: sales@optisurf.com

web: http://www.optisurf.com

Related News

- Custom Time Delay Integration Image Sensors 2/26/2026

- VALIDOGEN Introduces Next-Generation Synthetic Methanol-Free Promoters for Pichi 2/26/2026

- Custom Endoscopes for High Temperature Imaging 2/25/2026

- Flat Film Degasser Offers Superior Efficiency and Improved Compatibility 2/19/2026

- ProBioGen Introduces CMC Navigator™ to Help Biopharma Teams Select the Bes 2/17/2026

- MIMETAS and Partners Launch World’s First Microphysiological Systems Industry Al 2/11/2026

- Carterra Launches Industry’s First 48-channel HT-SPR Platform for Advanced Label 2/10/2026

- Highly Efficient Kit Yields Significant Populations of Pure Myogenic Cells 2/10/2026

- Ultra Smooth Hyperbolic Mirrors 2/9/2026

- Biotium Introduces Flexible, Time-Saving, and Cost-Effective Fluorescent Labelin 2/3/2026