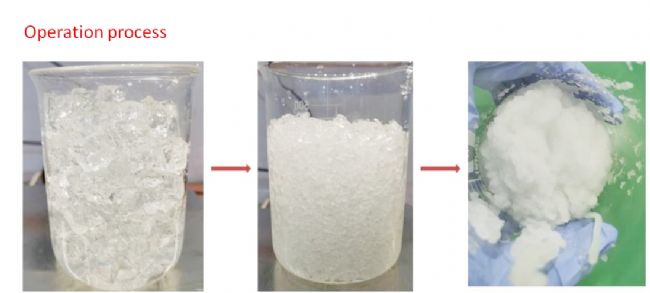

Gel granulator

The gel granulator is a granulator specially used for hyaluronic acid, gel and other high viscosity solutions, which can realize the preparation of 100-300um spherical particles

Product application: hyaluronic acid, gel, etc

Technical features:

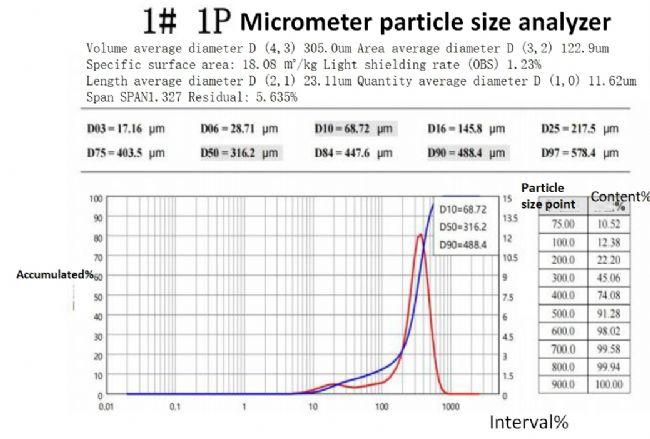

*Can achieve overall particle size preparation of 100-300um

*Contact material materials comply with cGMP requirements, FDA approved 316L and 17-4PH stainless steel, tungsten carbide, zirconia

And high molecular weight polyethylene, etc

*Design a high viscosity feeding system to fully address the flow issues of products with high molecular weight

*Minimum sample size: 20ml, suitable for expensive materials. Can design sample inhalation volume, no emptying, no waste

*Mechanical seal design, corrosion-resistant and high-pressure leak free risk

*Integrated extrusion system effectively controls the average particle size of hyaluronic acid

*Safety: The whole machine does not involve high-intensity air pressure and oil pressure, with intelligent overload protection

Equipment Usage: Used for the granulation of hyaluronic acid

1 Working conditions

1.1 Working voltage: 380V ± 10%, 50Hz

1.2 Temperature 10-80 ℃

1.2 Humidity 20-80%

2 Technical specifications and parameters

2.1: Treatment products: hyaluronic acid, gel, etc

2.2: Product process viscosity:<13000 CPS

2.3: Maximum feed particle size:<500 microns

2.4 Extrusion batches: 20ml, 50ml, 1000ml per batch

2.5: Minimum single batch processing capacity: 20 milliliters

2.6: Granulation module: Multi channel chip, can integrate 3P granulation system

2.7: Design power: 8000psi (safety protection value)

2.8 Adopting high-pressure sealing to enhance product stability

2.9 Adopting a high viscosity feeder to achieve stable product feeding

2.10 Power Supply: Suitable for 220V/380V 50Hz, 1.5Kw

2.11 Size and weight: 750 * 450 * 450cm/120kg, with a flexible and lightweight integrated design.

2.12 Control panel functions:

1: Control device start/stop

2: Set operating frequency

3: Display operating power

4: Data recording function

3 Basic configurations

3.1 Granulation host: 1 unit;

3.2 High precision digital pressure sensor: 1 set;

3.3 Porous microchannels: 1;

3.4 Variable frequency flow controller: 1 set;

3.5 One high viscosity feeder;

3.6 Two 20ml feeders;

3.7 Two 50ml feeders;

4 spare parts package

4.1 Standard tool wrench: 1 set

4.2 Whole machine sealing spare parts package: 1 set

4.3 Certificate of conformity: 1 copy;

If you have any questions, please feel free to consult,

pangjun@costones.com

bio-equip.cn

Suzhou COSTONES Instruments Co., Ltd. (COSTONES) is an instrument company focusing

on separation and purification. It is an equipment supplier and service provider

for biopharmaceutical, cell therapy and gene testing. It is committed to providing

users with industry-leading technical support and services.

The company has a perfect service system and executive power. It interprets the

user experience from the four aspects of technical communication, scheme design,

technical support and after-sales service, and tries to achieve seamless connection

in every link until it is recognized by customers.

For a long time, we have maintained good cooperative relations with domestic and

foreign suppliers. The main products include protein purification system,

compressible chromatographic column, ultrafiltration system, chromatographic

ultrafiltration accessories, etc., and provide maintenance services and customized

product services;

At present, Suzhou quarrying has provided high-quality services for

biopharmaceutical, cell therapy, research institutes and scientific research users.

It has carried out in-depth cooperation with customers and become a reliable partner

for customers to achieve win-win results.

We take quality first as the standard, quickly respond to customer needs, help

customers solve problems, improve efficiency, and take improving core

competitiveness for customers as our service tenet. We are willing to realize our

own value while creating value for customers and society through our unremitting

efforts.