- glass reactor system

- Product Detail

- Company Profile

Specifications

double layer glass reactor,Jacket glass reactor system

volume:1L-100L

Reacting tem:-80~300

GG17, SS,PTFE sealing,TOPTION

Double layer Chemical glass reactor,Jacket glass reactor system

1. volume:1L 2L 3L 5L 10L 20L 30L 50L 80L 100L

2. Reacting tem:-80~300

3. GG17, SS,PTFE sealing,TOPTION Brand

4. University brands designated

5. Explosion-prood device is optional

6. Ac motor,brushless,no sparkle

7. Constant rotationg speed

8. Reflow and distillation system

9.chemical laboratory use

10.reaction mixing vessel

TOPTION Double Layer Chemical Glass vacuum reactor is with double layer glass design, the inner layer placed reaction solvent can do the mixing reaction, the inter layer can be added with the different hot and cold sources (frozen liquid, hot water or hot oil) to do loop heating or cooling reaction. This jacketed glass reactor can be used to do high temperatureexperiment(max temperature is 280°C),as well aslow temperature experiment(min temperature is -80°C) and vacuum tests. It is an ideal equipment for chemistry small and medium-sized experiment,bio-pharmaceuticals and new materials synthesis. It also is used for extraction of gold.

The most important is that “the design of TOPTION reactor is unique,which can guarantee experiments of more convenient and safer.

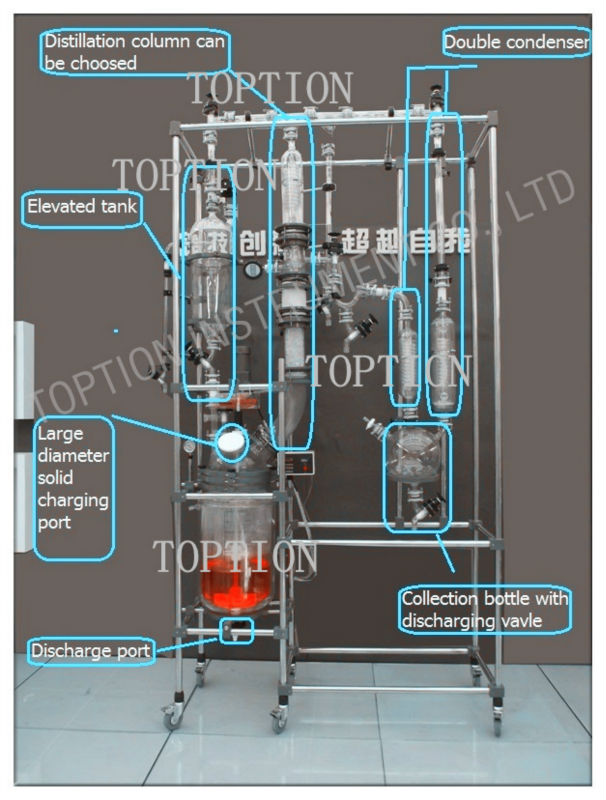

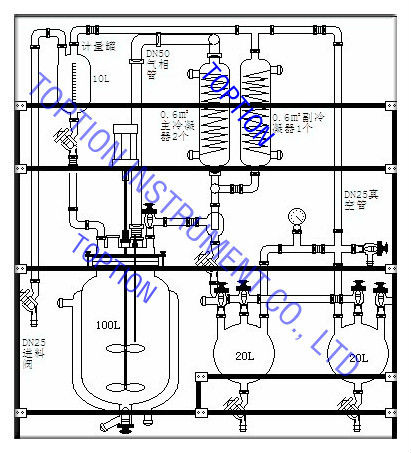

The structure of the 100L 80L 50L 30L 20L 10L 5Ldouble layer glass reactors :

Details information of structure double layer glass reactor:

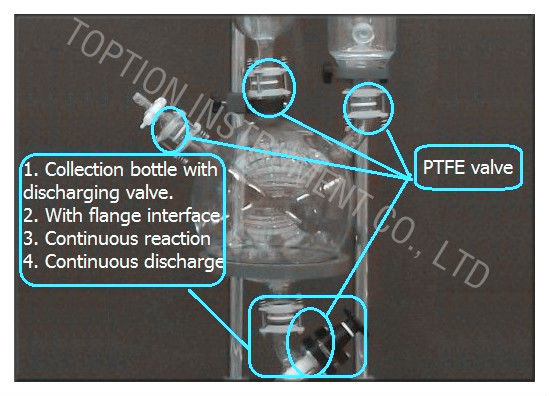

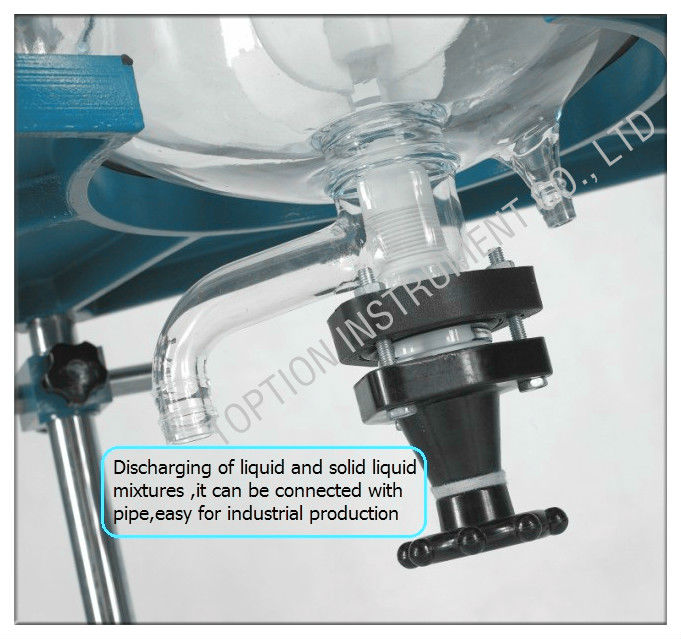

The collection bottle of TOPTION double layer glass reactor system is unique,we design big volume bottle with bottom discharge vavle.pls refer to the picture:

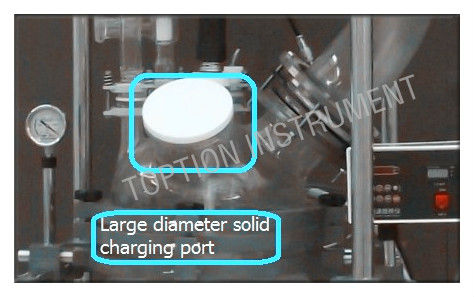

TOPTION double layer glass reactor with large diameter solid charging port.

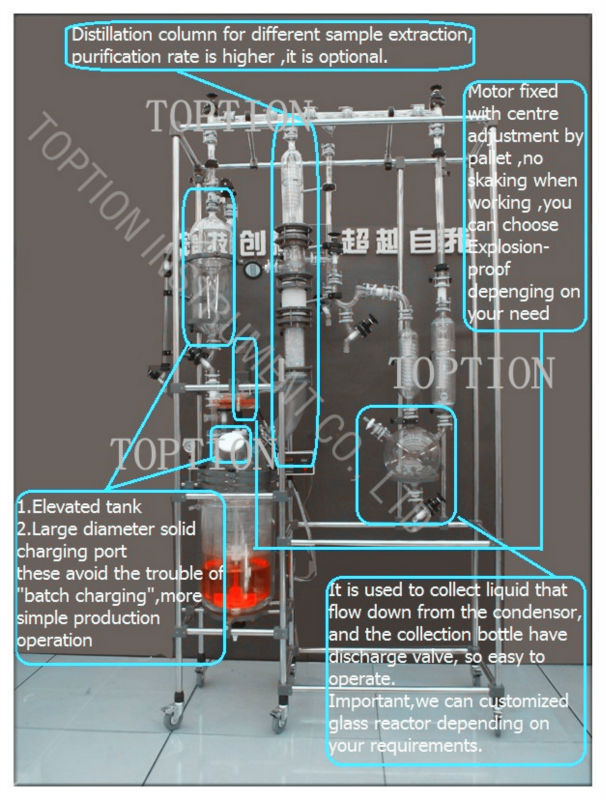

The Distillation column is optional with TOPTION glass reactor depending on your need.

The Elevaated tank is optional with TOPTION glass reactor , It can avoid the trouble of batch charging , more simple producting.

There are two bottom discharge vavles.

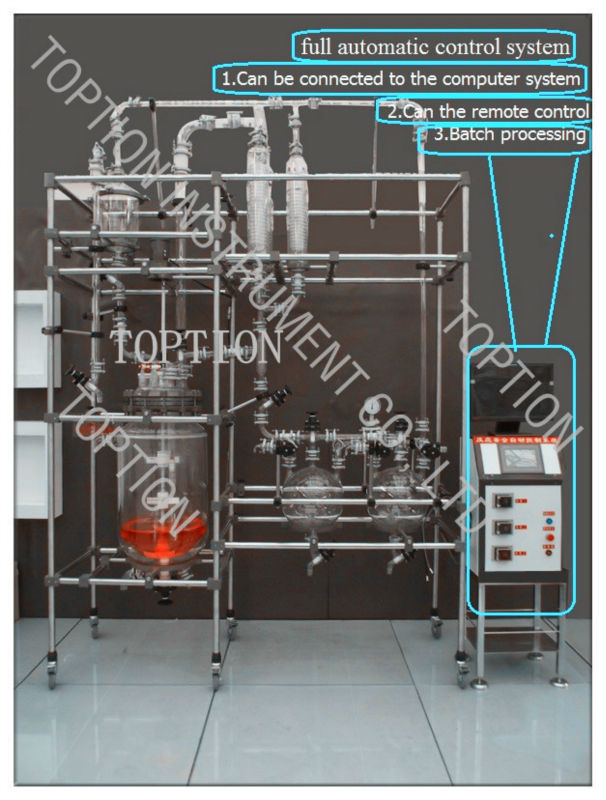

TOPTION company can customized glass reactor with full automatic control system,pls refer to the following:

We believe "TOPTION" will be your TOP OPTION!

The double-layer glass reactor of the company is the essence of the domestic similar products, with recommendations and experiences of all use customers, it has already been formed 1L, 2L, 3L, 5L, 10L, 20L, 30L ,50L and 100L series, the product design follows the efficient, practical and economic principles, all are for the users.

the special properties of glass reactors

1. double layer glass reactor adopts AC frequency control of motor speed So the rev is steady , no spark appear, wide moment, safe, and can be used as the constant working.

2. double layer glass reactor system use PTFE composite seal, it can maintain high vacuum degree.

3. glass reactor system use efficient condenser to ensure high recovery rate.

4. The complete set of double-layer glass use GG17 high borosilicate glass with good chemical and physical properties. The thickness of the glass is 5-7 mm with good chemical and physical properties

5. The glass inter layer interface is added with hot oil, through the loop, it can do reaction under the condition of high temperature; the glass inter layer interface added with cooling fluid can carry on reaction under the condition of low-temperature.

6. the double-layer glass reactor system can be added with tap water to quickly take away reaction heat.

7. Double-layer glass reactor discharged material has flanged opening and PTFE valve, without dead angle inside the container, it can be demounted to facilitate the discharge of solid materials.

8. Double-layer glass reactor have digital mixing motor, frequency conversion control, matched with a torque increasing of reducer.

9. Double-layer glass reactor system reasonable structure and selected materials. The mechanical components use stainless steel and aluminum-alloy pieces, the glass pieces use high borosilicate glass with high temperature resistance and good chemical properties. Electrical components parts: the main components use original imported devices.

10. Double-layer glass reactors cover opening design: constant pressure hopper opening (or as inlet), condensation reflux inlet, thermometer bushing opening, solid feeding opening (or as outlet) and mixing opening.

11. the range of glass reactor stirring rate is 10-1100 r/min.

12. The gas can be condensed through condenser system.or release valve.

13. control its pressure inside, by vacuum pump or pressure pump. But the price of pump is additional. Now , the glass reactor was had a pressure gauge, can display the pressure value, but there is no way to charge into the positive pressure or negative pressure, but only display pressure.

14. Our glass reactor is thermoresistant material. Glass material is G3.3, and extreme temperatures: low temperature to -80and high temperature to 300..

15. . This glass reactor has a heating jacket for oils, water to go through and heat.

16. Warranty period is: one year after the time that the demand side received the equipment.

The function of glass reactors system

The double-layer glass reactor system realizes one reactor severs several purposes in the experiment, satisfying diversify of aspects of different tests. It can be used for the following reactions:

1. Vacuum stirring reaction

2. High-temperature and low-temperature reaction

3. Constant speed running mixing reaction

4. Distillation , refluence and condensation reaction.

5. Negative pressure operation and separation

6. To do the rectify through assembling the rectifying pillar. Realize Reflow and distillation.

7. Assembly the production line in accordance of the specific demands. Customize new products based on clients different demands.

We believe the quality will not let you down. TOPTION company can custimezed various specifications of glass reactor system, we believe "TOPTION" will be your "TOP option".

Welcome To Customized Design! Pls don't hesitate to contact us, Welcome!!!

Basic parameter:

|

type

|

volume (L) |

Motor power (W) |

Speed (r/min)

|

Stirring torque(1300r/min) |

Inside/outside tube diameter (mm) |

Reactor vessel cover relevant opening size |

||||

|

center |

left |

right |

later |

before |

||||||

|

TOPT-100L |

100 |

250 |

10-680

|

22000g.cm |

460*500 |

50# |

40# |

34# |

34# |

29# |

|

TOPT-80L |

80 |

250 |

22000g.cm |

460*500 |

50# |

40# |

34# |

34# |

29# |

|

|

TOPT-50L |

50 |

180 |

15000g.cm |

360*405 |

50# |

40# |

34# |

34# |

29# |

|

|

TOPT-30L |

30 |

180 |

15000g.cm |

315*360 |

50# |

40# |

34# |

34# |

29# |

|

|

TOPT-20L |

20 |

120 |

12000g.cm |

315*360 |

50# |

40# |

34# |

34# |

29# |

|

|

TOPT-10L |

10 |

120 |

12000.g.cm |

245*260 |

50# |

40# |

34# |

34# |

29# |

|

|

TOPT-5L |

5 |

90 |

9000.g.cm |

200*230 |

50# |

29# |

24# |

24# |

19# |

|

|

TOPT-3L |

3 |

60 |

5000.g.cm |

200*230 |

50# |

29# |

24# |

---- |

19# |

|

|

TOPT-2L |

2 |

60 |

5000.g.cm |

150*180 |

50# |

29# |

24# |

---- |

19# |

|

|

TOPT-1L |

1 |

40 |

2400.g.cm |

150*180 |

50# |

29# |

24# |

---- |

14# |

|

Tel:0086-29-88763980

Fax:0086-29-88990306-8006

Skype:Kellin198

Email:kellin@toption-china.com

-

Xi''an Toption Instrument Co., Ltd. was founded with the total area of more than 4,000 square meters, located in Science and Technology Industrial Park, Gaoxin District, Xi''an City. We are an integrated company gathering the development, production and sales with independent legal personality. Our aim is: Keeping Credibility, Honoring Contract and Providing Products with High Quality and Excellent Performance.

Xi''an Toption Instrument Co., Ltd. respectively carries out the R&D and production of precision instruments and test infrastructures. The brand for all products of our company is TOPTION. Since establishment, several series of a variety of products have been developed and produced: multi-function photochemical reactor systems, (UV, visible lights, simulated sunlights, halogen light sources, antimony light sources and other different light sources), double glass reactors, three-layer glass reactors, rotyary evaporator systems, chillers, low-temperature cooling liquid circulating devices, low-temperature thermostatic baths, low-temperature cooling liquid circulating pumps, high-precision low-temperature thermostatic baths, low-temperature thermostatic circulators, ultrasonic cell crushers, ultrasonic extraction equipment, ultrasonic material emulsifying dispersers, freeze-drying machines, snow ice machines, chromatography experiment refrigerators, ultrasonic cleaning machines, sterile homogenizers, incubators, drying ovens, PCR instruments, electrophoresis apparatuses, electrophoresis tanks, membrane separation and purification equipment, spray drying equipment and other lab-equipment. Our products sell well around the world and gain a good reputation in many universities and colleges and scientific research institutions.

Xi''an Toption Instrument Co., Ltd. has specialized temperature control technical personnel and advanced production equipment as well as perfect production process. We have established a complete quality management system to ensure product quality and achieve safe production. We strive to produce beautiful, practical, stable and cost-effective products and save more experimentation space for our customers. We will always provide you with safe, stable and high-performance test equipment to make you more relaxed during the experiment.

TOPTION wholeheartedly provides high-quality products and reliable after-sales service for research institutions, universities and colleges, drug testing, chemical industry, metallurgy, biochemistry and key food processing projects. We sincerely serve you forever!

We believe TOPTION will be your top option!

| Request Information |

| Other Products |

| Related Products |

| Recently viewed products |

- SiteMap