Why Separate Manure?

The separation of manure into its solid and liquid components is important for two reasons.

Firstly, the value of dry manure is much more than that of the wetter kind.

Secondly, dry manure solids' transportation is practical and cost-effective compared to manure cost with a large water percentage.

Besides, the solids' physical separation reduces the phosphorus, which is crucial for the separated water's disposal consideration.

Separation Process

The separation of manure is the process of fractionating the manure into its liquid and solid phases. Separated manure sludge yields more value as a fertilizer and is easy to transport.

The water separated from the manure is mostly free of solids and nutrients, making it suitable for disposal. Dewatering centrifuges play a critical role in this application.

Physical means of manure separation range from gravity separation in lagoons to media separation devices (presses) and mechanical separator centrifuges.

Though each separation method has a role in the livestock industry waste management, the decanter centrifuge is the most durable, cost-effective long-term solution.

Operation

Operation

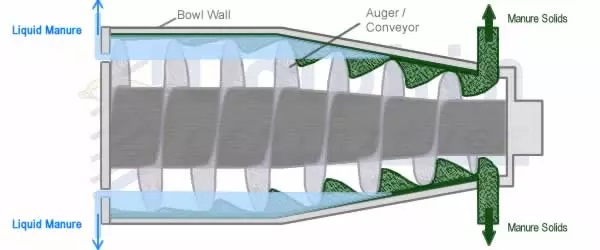

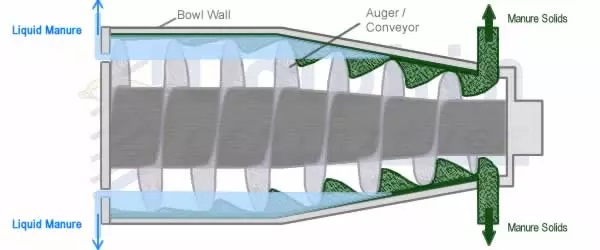

A manure centrifuge separates manure solids from the water using high centrifugal forces over 3,000 Gs. The solids are heavier and settle out to the rotating bowl wall.

The relatively lighter water stays in the center and flows out the liquid end. The rotating conveyor scrapes the manure solids to the solids' end of the bowl.

It is important to note that most Phosphorus is bound to the solids and therefore ends up the separated solids. About 50% of the Nitrogen is retained in the liquid manure.

Introducing some chemical flocculants enhances the separation process, allowing smaller particles, less than 50 µm, to be separated.

Two-phase decanter centrifuge parameters are tailored for optimal performance.

|

Model

|

|

Length mm

|

Rotation speed(Rpm)

|

separation factor

|

capacity

|

Main motor

|

Vice motor

|

|

|

LW250*1000

|

|

1000

|

4800

|

2722

|

0.5-5

|

7.5

|

4

|

950

|

|

LW300*1200

|

|

1200

|

4000

|

2688

|

1-8

|

11

|

7.5

|

1350

|

|

LW355*1160

|

355

|

1160

|

3600

|

2576

|

2-8

|

15

|

7.5

|

1400

|

|

LW355*1460

|

355

|

1460

|

3600

|

2576

|

2-10

|

15

|

7.5

|

1800

|

|

LW355*1460H

|

355

|

1460

|

3600

|

2576

|

2-10

|

15

|

7.5

|

2000

|

|

LW420*1750

|

420

|

1750

|

3200

|

2406

|

4-20

|

30

|

11

|

3000

|

|

LW450*1600

|

450

|

1600

|

3200

|

2578

|

5-25

|

30

|

11

|

3500

|

|

LW450*1800

|

450

|

1800

|

3200

|

2578

|

5-28

|

37

|

22

|

3600

|

|

LW450*2000

|

450

|

2000

|

3000

|

2266

|

5-30

|

37

|

22

|

3800

|

|

LW500*1800

|

500

|

1800

|

3000

|

2517

|

10-32

|

45

|

22

|

4300

|

|

LW500*2000

|

500

|

2000

|

3000

|

2517

|

10-35

|

45

|

22

|

4500

|

|

LW550*1800

|

550

|

1800

|

3000

|

2769

|

10-40

|

45

|

22

|

4800

|

|

LW550*2200

|

550

|

2200

|

2800

|

2412

|

10-45

|

45

|

22

|

5000

|

|

LW650*1750

|

650

|

1750

|

2000

|

1454

|

20-50

|

90

|

30

|

6000

|

|

LW650*2000

|

650

|

2000

|

2000

|

1454

|

20-55

|

90

|

30

|

6200

|

|

LW720*2000

|

720

|

2000

|

1800

|

1450

|

40-100

|

110

|

55

|

10000

|

Benefits

- Higher Value of Liquid Manure

The centrifugal solids separation leaves the separated liquid with minimal Phosphorus. This reduction in P-content vastly increases the applicability of liquid manure as fertilizer.

- Reduced Storage and Transportation Costs

Separated phases (solid and liquid) are much easier to handle and store as needed. Solids can be further dried and stored for longer terms. Considerable reduction in volume is the key to transportation-related cost benefits.

- Higher Value Fertilizer

The retained nutrients and Phosphorus in the separated solids can be used as periodic fertilizer or even sold as a more organic substitute for expensive, commercial chemical fertilizers.

- Dredging Cost Savings

Upfront solids separation using a centrifuge means lesser solids end up in the open pits or lagoons. The storage pits maintain their capacity without needing frequent dredging to reclaim storage volume.

Advantages Over Filter Press

Centrifuges offer many advantages over other mechanical separation devices like filter presses, belt presses, etc.

- Separation Efficiency

With centrifugal forces over 3,000 Gs, centrifuges can separate solids in the 25 ~ 50 µm range. Other conventional technologies only go down to 300 µm level or higher.

- Drier Solids

Solid cake dryness is adjustable with a decanter centrifuge. Solids with 50% dryness are attainable using pond-depth adjustment of the centrifuge. Drier solids are easier to transport and readily applicable as fertilizer.

- Reduce or Eliminate Chemical Use

With the use of centrifugal force to enhance separation, flocculants and other separation aids are significantly reduced, leading to immediate cost savings.

- Minimum Labor Cost

The purely mechanical separation offered by centrifuges allows for unattended and reliable separation of manure solids. This reliability reduces labor costs associated with presses and other mechanical separation methods.

- No Media Costs

Since centrifuges do not use any separation media (like filter mesh, paper, or cloth), recurring costs related to such consumables are eliminated. This saving also reflects on the used media disposal costs.

bio-equip.cn

Operation

Operation