Home >Products> Centrifuges >Other Centrifuges> Pharmaceutical Grade Herbal Liquid Separator Tubular Centrifuge

Centrifuges :

High-speed Refrigerated Centrifuges

Large-capacity Centrifuges

Benchtop Centrifuges

Other Centrifuges

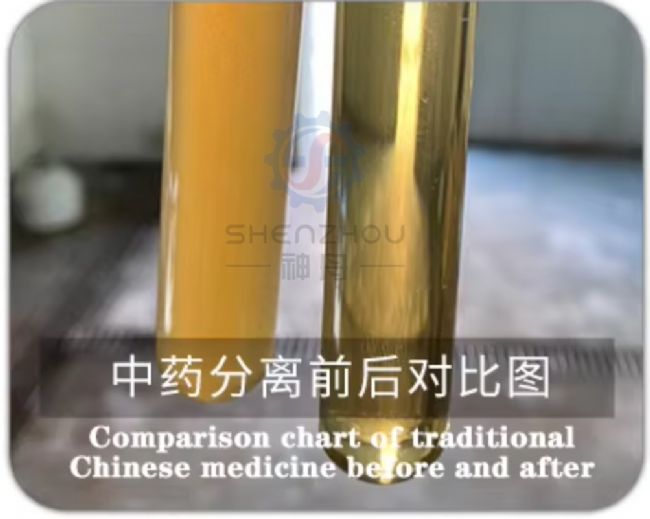

- Pharmaceutical Grade Herbal Liquid Separator Tubular Centrifuge

| Request Information |

| Related Products |

| Recently viewed products |