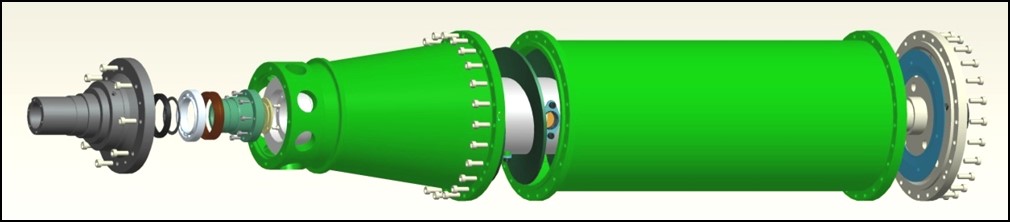

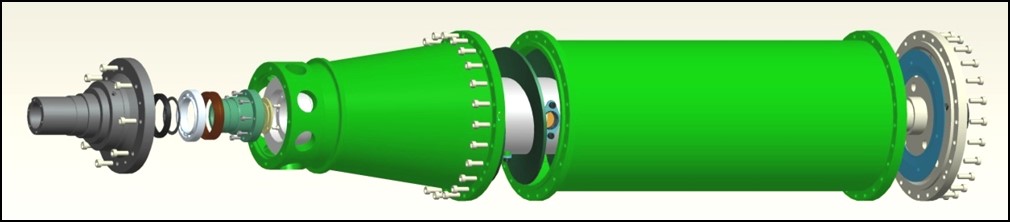

三相卧螺离心机主要用于物料的固-液-液三相分离。凭借我们在分离行业10多年的经验,它是最先进的三相分离机器。它专为全天24小时连续平稳运行而设计。主要由驱动系统、滗水器转筒、转筒内螺旋输送机、盖箱、撬块和VFD控制面板组成。

为确保分离过程能够进行,固相必须是特别重的相,并且两个液相必须具有不同的密度。 2 相倾析器和 3 相倾析器之间的主要区别在于,3 相倾析器不仅分离固体,但也分离液体的两相。https://www.alibaba.com/product-detail/Decanter-Centrifuge-Vaste-En-Vloeibare-Scheiding_1600327667698.html?spm=a2700.galleryofferlist.normal_offer.d_title.5bc467203ZYyad&s=p

三相滗析器广泛用于油、水、固分离行业。

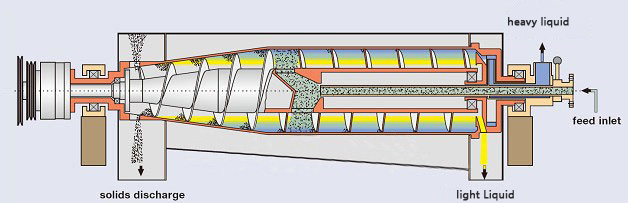

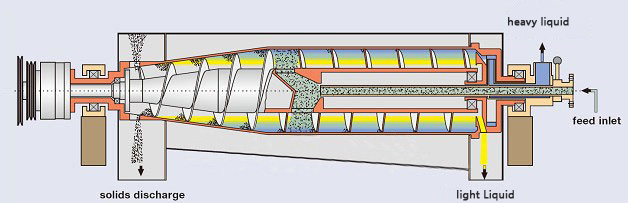

三相卧螺工作原理

The three-phase decanter centrifuge operation is based on the principle of sedimentation, that is, solid particles with specific liquid weight precipitate in a predetermined time. This principle can also be applied to two immiscible liquids with different specific gravity. When the material enters the high-speed rotating drum, the material rotates synchronously with the drum. Because of the different specific gravity, the centrifugal force is different. The solid particles with the larger specific gravity are subjected to the greatest centrifugal force, followed by the heavy phase liquid (such as water) and the light phase liquid (such as oil). So the centrifugal force is becoming less from outside to inside according to the magnitude of centrifugal force. A concentric solid layer and two liquid layers are formed. Solids are pushed out by the screw conveyor, and liquids are removed from their respective nozzles. Therefore, the application of three-phase decanter centrifuge can not only separate the solid in the material, but also separate the two-phase liquid with different specific gravity in the material, that is, Solid-liquid-liquid separation can be achieved.

3 PHASE DECANTER SPECIFICATIONS

| Model |

LWSX-350 |

LWS-450 |

LWS-520 |

| Type |

Continues Oil / Water / Solids Separation |

| Bowl Dia |

350mm |

450mm |

520mm |

| Bowl Length |

1540mm |

1800mm |

2132mm |

| Capacity |

5 m3/h |

10 m3/h |

15m3/h |

| Max Speed |

4000 RPM |

3600 RPM |

3000 RPM |

| Max G Force |

3136 G |

3260 G |

2620 G |

| Diff. Speed |

2-25 RPM |

5-25 RPM |

5-25 RPM |

| Main Drive |

22 KW |

37 KW |

55KW |

| Back Drive |

5.5 KW |

15 KW |

15KW |

| Lubrication |

Grease/Oil |

Oil Pump |

| Oil Pump Size |

N/A or 0.37KW |

0.37 KW |

0.37 KW |

| Feed Material |

Solids Less 10% and Particle Size less than 2mm |

BOWL ASSEMBLY FEATURES

- Bowl Material: Duplex Stainless Steel SS2205

- Solids Discharge port: Tungsten Carbide insert

- Bearing: SKF or Japan NSK Brand

- Gearbox type: planetary wheel type

- Screw Conveyor Material: Duplex Stainless Steel SS2205

- Material Distribution Nozzle: : Tungsten Carbide insert

- Screw Conveyor Wear Protection: Tungsten Carbide Tiles

- Differential Speed: Adjustable according to conditions

- Bearing: SKF or Japan NSK Brand

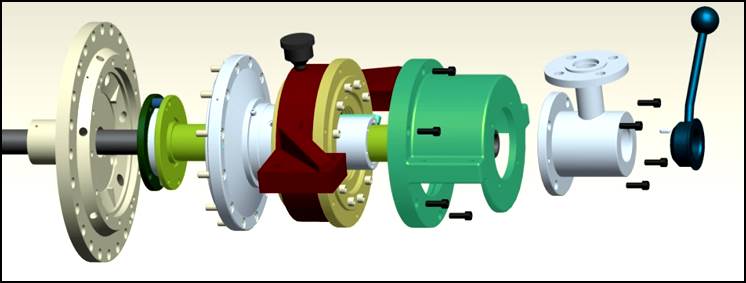

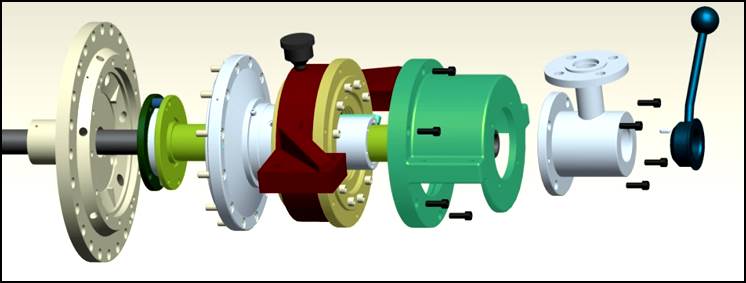

3 PHASE DECANTER ADJUSTABLE SEPARATION

Flexible for different Liquid Phase Proportion

An adjustable impeller discharges the "heavy" liquid phase. Furthermore, the operator can use the adjustable impeller to adjust the pond depth of the heavy liquid without difficulty during ongoing operation. According to the Proportion of two different phase, An adjustment mechanism causes the position of the impeller to change, thus changing the separation line of the liquids. The process engineering results can thus be influenced so as to achieve the required separation result.

bio-equip.cn