Home > News > Improving the Lifetime and Performance of High-power Laser Mirrors

Improving the Lifetime and Performance of High-power Laser Mirrors

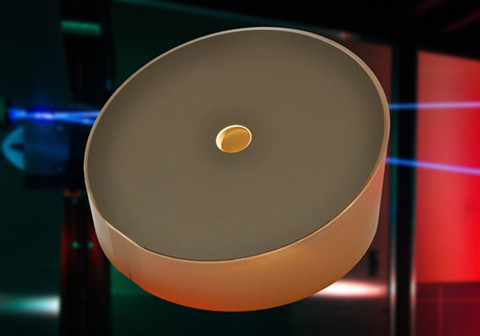

- Optical Surfaces Ltd reports how its proprietary smoothing techniques largely eliminate surface microcrack damage from the off-axis parabolic mirrors it produces for high-power laser applications. As a result, the achievable performance and operational lifetime of these critical focusing mirrors is enhanced.

Surface microcracks introduced during machining processes such as grinding, can reduce the glass's intrinsic strength by creating stress concentration points. These defects not only compromise the optical element's structural strength and lifetime but also increase stray light thereby reducing the achievable focusing resolution of parabolic mirrors used in high power laser applications.

Off-axis parabolic mirrors for high-power laser applications (courtesy: Optical Surfaces Ltd.)

Benefiting from a highly stable production facility based deep inside a chalk cliff, Optical Surfaces skilled engineering team are world renowned for producing off-axis parabolic mirrors with surface accuracy, surface microroughness and surface slope errors at the limit of what is possible.

Dr Aris Kouris of Optical Surfaces said “Few companies in the world can produce off-axis parabolic mirrors of sufficient quality to enable Petawatt and Zettawatt lasers to focus their massive energy down onto targets only a few microns in size. Our ability to routinely produce ultra smooth parabolic mirrors not only helps research group advance the boundaries of what is experimentally possible but also extends the mirrors operational lifetime.”

Off-axis parabolic mirrors provide an unobstructed aperture and access to the focal plane. In addition, due to their completely achromatic performance, they are especially suitable for broadband or multiple wavelength laser applications. Many optical and system designers favour off-axis parabolic mirrors as they often provide the most cost-effective answer without any compromise in performance and present the ideal solution to many high-power laser applications.

For further information please visit https://optisurf.com/off-axis-paraboloids/ or contact Optical Surfaces Ltd. on +44-208-668-6126 / sales@optisurf.com.

Optical Surfaces Ltd has been producing high precision optical components and systems for more than 60 years. The company’s ISO 9001-2015 approved manufacturing workshops and test facilities are deep underground in a series of tunnels excavated in solid chalk where temperature remains constant, and vibration is practically non-existent. With such stable conditions testing, particularly with long path lengths, becomes quantifiable and reliable.

-----------

Worldwide HQ

Optical Surfaces Ltd.

Godstone Road

Kenley

Surrey CR8 5AA

UK

Tel. +44-208-668-6126

email sales@optisurf.com

web http://www.optisurf.com

Related News

- Low Binding DNA Consumables for NGS and Molecular Biology 1/30/2026

- Creative BioMart Launches GenePowerTM Controlled Randomization to Support Precis 1/29/2026

- Biotech Fluidics: Instrument Optimized Vacuum Degassers. 1/28/2026

- High Speed Framing Cameras for Fusion Research 1/21/2026

- Tri-coded Storage Tube Optimized for Maximum Sample Recovery 1/16/2026

- Optimised UV Lenses for Forensic Investigation 1/16/2026

- Large Format Aerial Surveillance Lens 1/7/2026

- Breathing New Life into Older High-speed Cameras 1/7/2026

- New Handheld Decapper Boosts Speed and Consistency of 48-Format Tube Handling 1/6/2026

- Celleo Biotech Uses INTEGRA's PIPETBOY GENIUS to Improve Reproducibility and Eff 1/5/2026