How Product Resistance Impacts Primary Freeze Drying

SP Scientific, a world leader in freeze drying technology, has released an informative new technical article authored by Dr. Margit Gieseler, GILYOS GmbH and Dr. Henning Gieseler, Freeze Drying Focus Group, University of Erlangen which discusses the impact of product resistance on primary freeze drying.

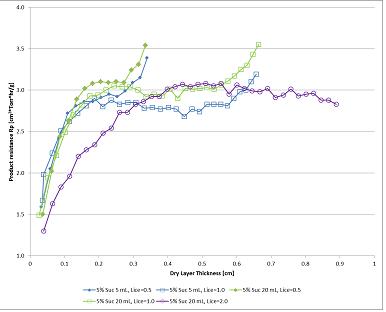

Freeze drying is known to be a time consuming process with primary drying phases ranging from several hours up to weeks, depending on the product. During primary drying the product temperature at the ice sublimation interface (Tp) must not exceed the critical formulation temperature (collapse or eutectic temperature, respectively) to prevent impairment of final product quality by collapse or meltback. Tp is determined by several factors like chamber pressure, shelf temperature, vial heat transfer coefficient and resistance of the dried layer.

The new technical article** discusses how product resistance (Rp) has been recently suggested as a critical product parameter (CPtP) in freeze drying because it instantaneously draws a picture of the (already dried) inner cake morphology at the point of measurement. From a physical point of view, Rp of the dried product layer impacts the resistance to water vapour flow and thus indirectly determines the maximally allowable shelf temperature and primary drying time.

Further to providing an informative introduction to product resistance behaviour the article summarises the results of trials investigating the product resistance of sucrose based on different experimental conditions and using the Auto-MTM feature of the SP Scientific SMART Freeze Dryer software. The authors conclude resistance of the product to vapour flow during primary drying is a critical product parameter that impacts several process parameters. Lack of information about product performance during primary drying can lead to sub-optimal product quality and/or problems during scale-up. The use of MTM allows an easy and reliable assessment of product resistance data.

To access a copy of 'The relevance of product resistance in freeze drying' please visit the SP Scientific website** or contact the company on telephone +1-845-255-5000 (+44-1473-240000 in Europe).

SP Scientific (www.spscientific.com) is a leading manufacturer of laboratory-to-production scale freeze dryers / lyophilizers, centrifugal evaporators and concentrators, thermal control system and glassware washers. The company is comprised of well-known brands including VirTis®, FTS™, Genevac® and Hotpack®. SP Scientific has ISO 9001:2008 registered production facilities in the USA and Europe.

** Web link: http://www.spscientific.com/LyoTech-Center/LyoLearn-Tech-Brief.aspx#item36

Worldwide Headquarters

3538 Main Street

Stone Ridge

NY 12484

USA

Tel: +1.845.255.5000

Genevac Ltd.

Farthing Road

Ipswich IP1 5AP

UK

tel. +44-1473-240000

email salesinfo@genevac.co.uk

- MIMETAS and Partners Launch World’s First Microphysiological Systems Industry Al 2/11/2026

- Carterra Launches Industry’s First 48-channel HT-SPR Platform for Advanced Label 2/10/2026

- Highly Efficient Kit Yields Significant Populations of Pure Myogenic Cells 2/10/2026

- Ultra Smooth Hyperbolic Mirrors 2/9/2026

- Biotium Introduces Flexible, Time-Saving, and Cost-Effective Fluorescent Labelin 2/3/2026

- Low Binding DNA Consumables for NGS and Molecular Biology 1/30/2026

- Creative BioMart Launches GenePowerTM Controlled Randomization to Support Precis 1/29/2026

- Biotech Fluidics: Instrument Optimized Vacuum Degassers. 1/28/2026

- High Speed Framing Cameras for Fusion Research 1/21/2026

- Tri-coded Storage Tube Optimized for Maximum Sample Recovery 1/16/2026