1.Capacity: 0.5L,1L,2L,3L,5L,10L,20L,30L,50L,100L,150L,200L.

2.High temperature: RT-300℃ (heater optional).

3.Low temperature: RT- -80℃ (chiller optional).

4.Vacuum pump & vacuum controller are available.

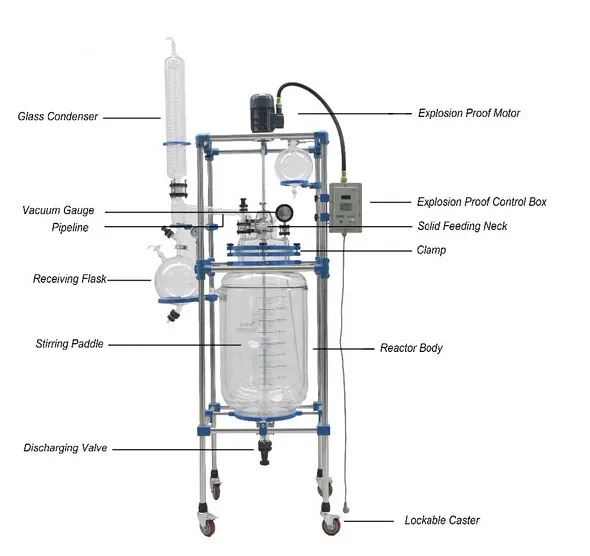

Double layer Jacketed double layer Glass Reactor

Application of min lab jacketed glass reactor

- Vacuum Distillation

- Multi-component reactions

- Gas introduction into liquid phase

- Extraction of multi phase mixture

- Crystallization

- Reflux

- Multiple chemical reactions liquid/liquid, liquid/solid

- Low temperature chemistry

- Cell Culture

Techinical parameter of min lab jacketed glass reactor

Jacketed Double layer Glass Reactor Key Features:

1. Double glass reactor using VVVF, AC Induction Motor. Speed constant, no brush, no sparks, security staTOPTe, continuous working.

2. Complete glass reactor adopts GG17 high borosilicate glass production good chemical, physical properties.

3. Glass interlayer Interface communication on hot oil through cycle do Heating Reaction, Tung on cryoprotectants can be hypothermia reaction.

4. Can normal temperature reaction, pass last tap namely quickly will reflect heat away.

5. Decentralization material mouth with flange mouth and PTFE valve, container no dead corner detachaTOPTe easy solid materials outfeed.

6. 5 reactor lid, large mouth design easy clean standard mouth socket selectaTOP Te assem TOPT reflux, distillation synthesis device

Advantage and benifit of min lab jacketed glass reactor

1. Low temperature device is available, low temperature could reach -40℃, satisfy your special research requirements of low temperature -40℃. Jacketed glass reactor is ideal pilot and production equipment of modern fine chemical plant, biological, pharmacy and new materials synthesis.

2. Professional and resonable design of glass jacketed layer discharge outlet.

1) After reaction finish,the cooling or heating solution in glass jacketed layer can be discharged completely,

no hydrops.

2) You could keep interlayer clean convenient and easy,so as to make the jacketed layer cooling and heating

function is valid,and ensure the necessary cooling or heating conditions for your research.For long time,make

your research keep accurate.

Products Details

Choose TOPTION as your lab solution provider, please begain from understanding the top detail quality of our

glass reactor, through more than 10 years striving continuously, TOPTION brand lab instrument such as glass

reactor, rotary evaporator, photochemical reactor, freeze dryer and spray dryer, has own high reputation in more

than 70 countries and regions.

Alloy steel mechanical seals,PTFE connectors. This kind high precision mechanical seal could keep more better

vacuum degree about -0.095Mpa.

PTFE stirring paddle is suitable for low to high viscosity liquid stirring and mixing. Increase the range of material

viscosity which you could choice.

ISO & CE quality certification, products' quality management system, for every delivery instrument, we have professional

quality manager team to cheak, then sign product certification and warranty card. Protect your research and business safe.

Strong specialist team who have more than 10 years experience, provide unique customization of double layer glass

reactor according your actual research needs, only most suitable glass reation vessel could make your research

most efficient:

Engineers test instrument and control products' quality during whole production process, as TOPTION customer, you could

attend whole process and monitor your customized instrument production process in real time, before you purchase or

before instrument delivery, welcome you visit TOPTION lab instruments factory.

bio-equip.cn

Toption Company professional Lab solution provider ,mainly manufacture for glass reactor, stainless steel reactor, photochemical reactor, rotary evaporator, short-path molecular distillation, labglassware, freeze dryer , spray dryer, ultrasonic cleaner, ultrasonic homogenizer, and also deal kinds of oven & Incubator, Centrifuge, Autoclave, Shaker, Stirrer, Freezer,Fume Hood, Laminar Flow Cabinet, etc.