Description

Carbomix phases are composed of spherical, low cross-linking polystyrene/divinylbenzene (PS/DVB) particles with their surfaces modified with sulfonic acid (-SO3H), followed by chelating of metal ions of calcium (Ca2+), lead (Pb2+), sodium (Na+) or potassium (K+) to form Carbomix Ca-NP, Pb-NP, Na-NP, K-NP phases, respectively. The PS/DVB support has cross-linking degree of 5%, 8% and 10% with the particle sizes of 5 and 10 µm. The uniform particle size adds the benefit of high separation efficiency to Carbomix. Carbomix resins have been specifically designed for high resolution separation of carbohydrates, organic acids, peptides, and nucleic acids.

Packing

| Support: |

spherical, PS/DVB particles |

| Cross-linking: |

5%, 8% and 10% |

| Particle size: |

5 and 10 µm |

| Phase structure: |

hydrophilic, ion-exchange |

| Chemical composition: |

PS/DVB-SO3M (M: H, Ca, Pb, Na, or K) |

Characteristic

- Uniform particle size for high resolution and efficiency separation

- High stability

- High lot-to-lot reproducibility

- Long column life

- Compatibility with most aqueous mobile phases, including pure water as the eluent

- Wide range of operating temperature (0-85 °C)

- Low backpressure for the separation

- pH range (5-9) for Carbomix Ca-NP and (1-3) for Carbomix H-NP columns

|

| Conditions |

|

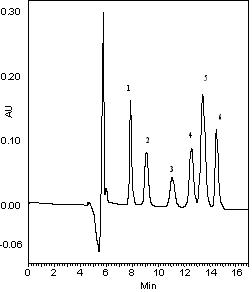

| Column: |

Carbomix Ca-NP5, 5µm, 8% cross-linking, 7.8×300mm |

| Mobile phase: |

nanopure water |

| Flow rate: |

0.6 mL/min |

| Backpressure: |

708 psi |

| Temperature: |

85 °C |

| Injection Volume: |

10 µL |

| Detector: |

UV 192 nm |

Sample:

(50 mM in H2O) |

1. Melezitose

2. Maltose

3. Glucose

4. Mannose

5. Fructose

6. Adonitol (N=64,200/m) |

|

Column Configuration

Carbomix resins can be packed into wide range of column dimensions with ID from 75 mm to 21.2 mm and the length from 5 cm to 30 cm. A custom-made column is also available. Column length and diameter affect resolution and analysis time. The selection of the column is to use only as much resin as necessary to achieve the desired separation. If the compound is strongly retained by the resin and analysis time is long on a 300 × 7.8 mm column, a shorter column, such as 150 mm long can significantly decrease the analysis time.

Separation Mechanism

The separation mechanism for the Carbomix Ca-NP phases includes ion-exchange and hydrophilic interactions with the analytes, such as carbohydrates and organic acids. The separation mechanism could also be due to size exclusion, ion exclusion, and ligand exchange. These multiple modes of interaction enable a unique capability to separate a variety of water soluble compounds. Resin cross-linking degree is an important parameter in the separation. Styrene divinylbenzene resin is a relatively rigid gel-type media. The lower the cross-linking, the more open the pore structure, and the more permeable it is to higher molecular weight substances. A 5% crosslinked Carbomix resin can resolve higher oligosaccharides compared to 10% cross-linked resin. For smaller molecular weight compounds an 8% crosslinked resin is used.

High Stability

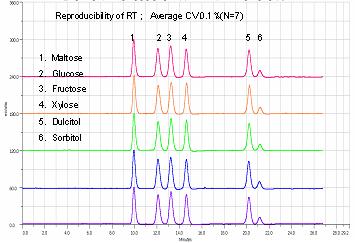

The Carbomix resins are stable in pure water and other aqueous buffers at elevated temperature. The reproducibility from run to run is very consistent. Figure below shows the retention time variation for 7 runs is only 0.1% for a Carbomix Ca-NP5 column.

Separation of carbohydrate mixture by a Carbomix Ca-NP5 column (5µm, 8% cross-linking, 4.6×300mm). (Courtesy of Miyako Kawakatsu, M&S Instruments, Inc.)

|

| Conditions |

|

| Mobile phase: |

nanopure water |

| Flow rate: |

0.2 mL/min |

| Backpressure: |

76 bar |

| Temperature: |

85 °C |

| Injection Volume: |

10 µL |

| Detector: |

ELSD |

Sample:

(6 mg/mL in H2O) |

Maltose

Glucose

Fructose

Xylose

Dulcitol

Sorbitol |

|

High Lot to Lot Reproducibility

With well controlled polymer resin production and the surface chemistry, the manufacturing of the Carbomix ion-exchangers is highly reproducible. The typical variation of the retention time is less than 6% from batch to batch.

| Conditions |

|

| Column: |

Carbomix H-NP10, 10µm, 8% cross-linking, 7.8×300mm |

| Mobile phase: |

nanopure water |

| Flow rate: |

0.6 mL/min |

| Temperature: |

85 °C |

| Injection Volume: |

10 µL |

| Detector: |

RI |

| Sample: |

Citric acid

Succinic acid

Formic acid

Acetic acid |

Long column life

Figure below shows the reproducible injections at 5th, 150th and 300th run with 10µl galactitol on a Carbomix H-NP10 7.8×300 mm column.

| Conditions |

|

| Column: |

Carbomix H-NP10, 10µm, 8% cross-linking, 7.8×300mm |

| Mobile phase: |

5 mM H2SO4 |

| Flow rate: |

0.6 mL/min |

| Temperature: |

80 °C |

| Injection Volume: |

10 µL |

| Detector: |

RI |

| Sample: |

Galactitol |

bio-equip.cn Profile

Sepax Technologies, Inc., a privately held company, was founded in Delaware, USA in November 2002. It develops and manufactures HPLC consumables, bulk media, and equipment in liquid chromatography for chemical and biological separations. It is a fast growing technology company and owns patents, proprietary technologies and know-how. Sepax has emerged as a leader in the biological separation industry in the global market.

Business strategies

Sepax Technologies, Inc. develops innovative HPLC consumables, bulk media, and instruments to solve separation challenges in the global market. We provide solution-based products by closely working with our customer scientists in pharmaceuticals, biopharmaceuticals, research institutes and government labs. Our strong technical team develops various methods with our customers to analyze complex biological molecules. As a leader in the biological separation industry, we constantly develop the best bio-separation technologies and products for our global customers. We have reached a competitive position globally in fast growing regions.

Vision Statement

To become a technology leader in the biological separation industry in the global market and provide solution based products and services for our customers.

Operation

Sepax Technologies, Inc.

Our company headquarter in Delaware is located in Delaware Technology Park with facilities of 15,000 ft2 dedicated to the development of separation resin technologies and instrumentation, production of HPLC resins, columns and CE consumables. It is also the marketing and sales center for our US and global markets.

Sales

Domestic

Audrey Fisher

Field Sales Account Manager

(Northern CA areas, UT, CO, OR)

Direct Phone: 925-324-5223

Email: afisher@sepax-tech.com

Kathleen Falls

West Coast Regional Manager

(All other CA areas, WA, TX, AZ, NM, MI)

Direct Phone: 323-228-0004

Email: kfalls@sepax-tech.com

Michael Hunnewell

Field Sales Account Manager

(MA, RI, NH, CT, NY)

Direct Phone: 302-650-3955

Email: mhunnewell@sepax-tech.com

Colleen Callahan

Midwest Account Manager

(WI, IL, IN, OH, MO)

Direct Phone: 302-366-1101, ext 106

Cell Phone: 302-339-8747

Email: ccallahan@sepax-tech.com

All other areas, please contact

Helen Gu

Vice President, Sales

Direct phone: 302-650-3909

Email: hgu@sepax-tech.com

International

Tingting Wu

Executive Account Manager/Marketing

Phone: 302-366-1101, ext 115

Email: twu@sepax-tech.com

|