Description:

Milk Cream Separator Centrifuge Machine

1.The material of drum body, drum cover and valve is high strength stainless steel, the Moc of other parts are all high quality stainless steel, the disc stack and separator shell employ SS304.

2. Drive structure support use S-K-F bearing, by employing optimal design to reduce the height of the drum's center of gravity. It can effectively lower the vibrational level of the whole separator, improve the reliability of the equipment and increase the stability of the separator.

3. In the dismounting and maintenance, the parts of drum can be hoisted integrally, thus make the dismounting of main lock ring more convenient, saving both time and labor, easy to install the drum.

4. The separator has a less vibration and more stability through price dynamic balance of the drum.

5. The separator adopts separation factor technology. It can separate product that is hard to separate, meanwhile, the machine has light volume and use the small volume to get big capacity and high separation efficiency.

6. The separator adopts advance belt drive, improving the reliability and maintainability of the separator, and decreasing cost of spare parts.

Milk Cream Separator Centrifuge Machine Parameter

|

No.

|

Model

|

Clarify capacity

(l/h)

|

Degrease capacity

(l/h)

|

Drum diameter(mm)

|

Drum speed

|

Motor Power

(KW)

|

Discharge way

|

Separator factor

|

Weight

(kg)

|

Size

(mm*mm*mm)

|

|

1

|

RPDR230

|

1200

|

600-800

|

230

|

6930

|

2.2

|

Manual

|

6170

|

255

|

850X625X985

|

|

2

|

RPDH270

|

1800

|

800-1000

|

270

|

7200

|

4

|

Automatic

|

6950

|

550

|

865X645X1100

|

|

3

|

RPDH315

|

3000

|

1500

|

315

|

6500

|

5.5

|

Automatic

|

7000

|

650

|

900X600X1150

|

|

4

|

RPDH385

|

5000

|

2000

|

385

|

6500

|

7.5

|

Automatic

|

7500

|

750

|

1100X1050X1250

|

|

5

|

RPDH430

|

6000

|

3000

|

430

|

6900

|

11

|

Automatic

|

10000

|

900

|

1200X950X1400

|

|

6

|

RPDH470

|

10000

|

5000

|

470

|

6000

|

18.5

|

automatic

|

9500

|

1100

|

1250X1000X1550

|

Milk Cream Separator Centrifuge Machine

Features

* High speed centrifugation to remove oil grease and sludge impurities

* Strong emulsification ability

* Low energy consumption,saves money

* Full automation possible with PLC automatic control panel.

* Centrifugal separation requiring no filter media.

* High reliability drive train system backed by delivery of over 1,000 units a year.

* Bowl design with superior separation performance and with good response to discharge loads.

* Pilot valve regulates total/partial discharge of solids.

* Super partial discharger (option) minimizes liquid loss and maximizes thickening of solid

* Fraction for discharge.

* Vibration-proof design realizes long working life.

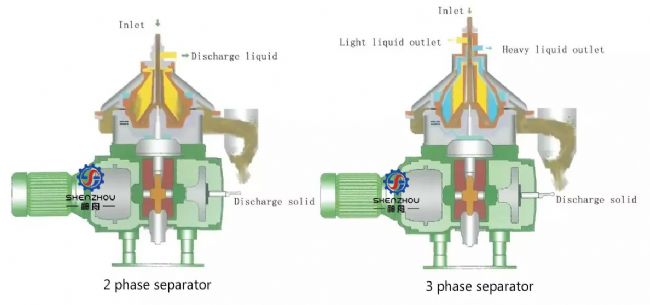

The disc separator is in vertical structure. The drum is mounted on the upper end of the vertical axis, which is driven by a motor and rotates at a high speed. There is a set of disc - shaped parts that are stacked together in the drum, with a small gap among them. When the suspension (or emulsion), which is pumped into the drum by feeding tube located in the center of the drum, pass through the gap between the discs, solid particles (or droplets) would settle down to form sediment (or liquid layer) on the disc by centrifuge force, and then the sediment slid along the surface of the disc and separated from the disc to accumulate in the largest diameter of the drum. At last, the separated liquid discharged from the outlet. The disc is utilized to shorten the settling distance of solid particles or droplets, enlarge the settlement area of the drum, and improve the production capacity of the separator. The solids accumulated in the drum are removed from the drum by manual after the machine stop, or out of the drum in the case of a dregs machine without stopping.

bio-equip.cn

Liaoyang Shenzhou Machinery Equipment Co., Ltd is a professional for supplier of pharmaceutical and chemical machine in China.We have a well-experienced team and a professional design institute,With rich experiences in pharmaceutical machinery and equipment including packing machine, centrifuge, falling film evaporator, distillation,mixer, tablet press machine, suppository production line,dryer,capsule filling machine ,capsule and so on.

WhatsApp:+8613130722088