Please contact below if you need more info:

Kevin Zhang

Shandong Saikesaisi Hydrogen Energy Co.,Ltd

Skype:kevinzhang696

Mobile(whatsapp):+8618615696905

Email: sales01@ql-spe.com

Tel: 86-531-58795166 Fax:86-531-58795199

NO.51 Gongyenan Road, High-tech district,Jinan,China

Specification:

-H2 flow :1Nm³/hr

-Hydrogen purity:99.999%

-H2 product outlet connector:

1\4"CPI Pressure pipe fittings(stainless steel)

-Dew point:-65°C/

-H2 output pressure:7bar

-Water consumption:<0.9L/H

-Input power:<5.2kW/H

-Voltage :AC,380v±10%,50-60Hz

-PLC fully wisdom control

Product introduction:

QLS series hydrogen generator which adopt PEM technology that electrolysis pure water (no add alkali),produce high purity hydrogen.It is a kind of high integration and automation, high-tech patented products.The systems benefit hydrogen users by improving supply reliability and site safety, while also reducing hydrogen storage space.

Application:

1.Hydrogen refueling station

2.Meteorology Balloon H2 filling

3.Hydrogen for fuel cell

4.Hydrogen supply for Power plant generator cooling system

5.Redundant Renewable energy transformation and storage

6.Hydrogen supply for Semiconductor fabrication

7.Materials processing

8.Heat treatment

9.Chemical and medicine or other laboratory

10.Other field that needing large and ultra pure hydrogen and oxygen

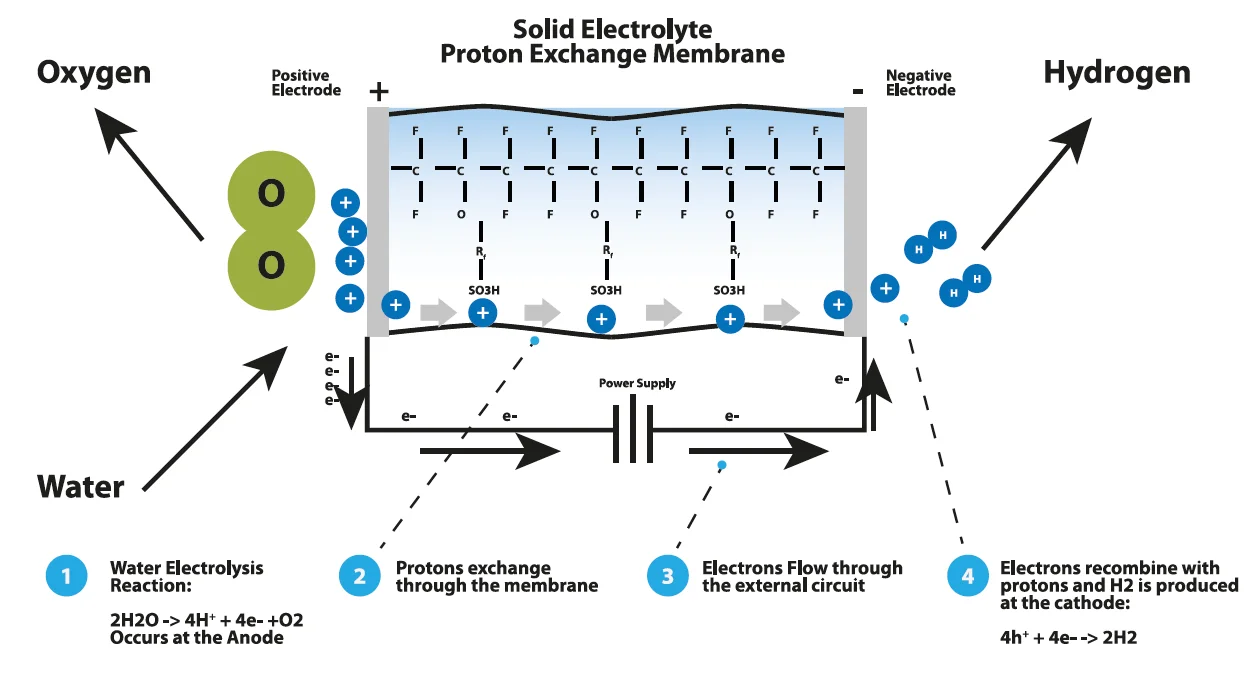

MAIN PRINCIPLE OF PEM HYDROGEN TECHNOLOGY

Saikesaisi’s hydrogen generation systems use a platinum catalyst and PEM (Proton Exchange Membrane )technology to split deionized water into its constituent parts.

The proton exchange membrane (PEM), which only allows water and positive ions to cross between compartments. The membrane also serves as the electrolyte in the cell, eliminating the need for hazardous liquid electrolytes such as concentrated potassium hydroxide. PEM water electrolysis simply splits pure deionized water (H2O) into its constituent parts, hydrogen (H2) and oxygen (O2), on either side of this membrane. When a DC voltage is applied to the electrolyzer, water fed to the anode, or oxygen electrode, are oxidized to oxygen and protons, while electrons are released. The protons (H+ ions) pass through the PEM to the cathode, or hydrogen electrode, where they meet electrons from the other side of the circuit, and are reduced to hydrogen gas. The two reactions that occur in the cell are as follows:

2.2H2O -> 4H+ + 4e- +O2

3.4H+ + 4e- -> 2H2

4.Thus, the only possible components of the streams are hydrogen, oxygen and water moisture, as shown in

Figure 1 below.

SPE/PEM Technology Advantages:

1. SPE technology---Solid Polymer Electrolyte

2. The SPE electrodes, as the core of the product, are highly active catalytic electrode with nearly zero distance between the electrodes, which is formed by integrating composite catalyst with ion membrane with high electrolytic efficiency.

3. Plural-electrode and multi-unit electrolysis cell structure. Excellent chemical technological process properties of heat and mass transfer,

3. Electrolysis of pure water (no adding alkali) to produce high purity 99.9995%) hydrogen with no corrosion and pollution.

4. Voltage of cell is low, electronic resistance in the electrolysis cell is little, could greatly saving energy. Circle time for changing desiccants is long.

5. Power consumption is less, electrolysis is efficient

6. Other parts of the generator are all produced by top-grade engineering plastics with superior quality.

7. Perfect electric control system. Stop working in emergency automatically.

8. Hydrogen Huge output, models are complete.Widely used in many industries

9. Got patent right, passed EU standard CE certificate, got top prize of BCEIA

Product Function Characteristics:

1.PEM(Proton Exchange Membrane) H2 generation technology

2.Electrolysis of pure water (without adding alkali) to produce hydrogen with no corrosion and pollution

3.PLC intelligent control, one-click start, stop

4.The DCS remote control system can be connected via Modbus TCP / IP protocol

5.User-friendly design,touch screen operation

6.High integrated site-ready enclosure,space saving

7.High reliability,stable hydrogen output flow

8.Automatically adjust output to match demand

9.Automatic leak detection system

10.Automatic fault detection and system decompression

11.The electrolysis efficiency is high, and power consumption is less.

WHY SAIKESAISI HYDROGEN TECHNO LOGY

Our company,Saikesaisi Hydrogen,is the earliest PEM hydrogen tech developer in China.Firstly established in 1993,got big investment from Saikesaisi Group in 2007 and change name to Shandong Saikesaisi Hydrogen Energy Co.,ltd.Till now Saikesaisi Hydrogen have specialized in R&D PEM hydrogen tech 24 years and have been biggest PEM hydrogen equipment factory in China.Ongoing research and development efforts have resulted in reliable systems that have evolved from China nuclear industrial to produce ultra-pure hydrogen to support critical commercial missions.

Please contact below if you need more info:

Kevin Zhang

Shandong Saikesaisi Hydrogen Energy Co.,Ltd

Skype:kevinzhang696

Mobile(whatsapp):+8618615696905

Email: sales01ATql-spe.com zld698AT163.com

Tel: 86-531-58795166 Fax:86-531-58795199

NO.51 Gongyenan Road, High-tech district,Jinan,China

bio-equip.cn

Shandong Saikesaisi Hydrogen Energy CO., Ltd. is a high-tech and strong innovation team. She has being engaged in producing PEM/SPE Hydrogen Generator from 1992. The chief technical expert is the first one developing PEM/SPE technology in China who has developed Four generation hydrogen generators and some have won the patens and fill in the vacancy in Chinese technology field.

The company choose SPE-Solid Polymer Electrolyte positive ion(proton) exchange membrane to electrolyze pure water which replaces traditional alkali liquor hydrogen production. This technology has won BECIA golden medal and certificate of patent.

Because of good quality, some products have got CE certification(No.E/EC13840511537). Now this company can supply the following products:

1.QL Series Hydrogen Generators (0-34000 ml/min).

2.SHC Series Hydrogen Generators(0-500 ml/min).

3.QL Series Pure Air Generator(0-300 l/min).

4.QL Series Nitrogen Generator(0-500 l/min).

5.QL Series Nitrogen and Air Generator(Nitrogen:0-300 ml/min, Air:0-1000 ml/min), Nitrogen, Hydrogen and Air Generator(Nitrogen:0-300 ml/min, Hydrogen:0-300 ml/min and Air:0-1000 ml/min).

6. Other customized generator and Accessory parts.

If you have any technical questions or need more detailed information about produces and company, please visit the website.