Split butterfly valve, ab valve, αβ Valve - Pneumatic Type

Material containment transfer technology

Fast and secure transfer for large quantities

Containment transfer

Economic solution

Supply solution for closed transfer of pharmaceutical materials

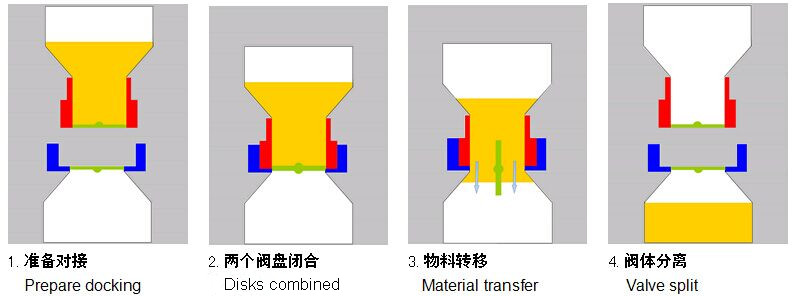

Split butterfly valve (Alpha Beta valve), is made up of an active and a passive valve. Adopts pneumatic method to control its working.

The transfer of material from one container to another container is being carried on sealing condition, and the sterile material transfer process guarantees the sterile situation won't be destroyed or avoid being spread of the powder, toxic materials in the container.

Interlock function: Only active valve and passive valve are mated completely, then can open the transfer channel.

When the transfer channel is opened, the passive valve cannot be disconnected.

Technical Parameter

- Valve disc surface sealing by metal to metal

-Body material: 316L stainless steel

-Sealing material: food grade FKM (meet FDA)

-Standard clamp interface, accept customized corresponding connection

-Outside of container operate valve switch and product transfer

-Comply with the new version of GMP, FDA, EU production requirements

Operation process

Purpose of use

a. Protection of sterile product-Guarantee transfer process of sterile product avoiding being effected by outside microbe

b. Operator protection- Avoiding leakage of toxic materials during transfer process which is harmful for people

c. Eliminate loss of product yield during transfer

d. Effective dust control during transfer process

e. Reduce the potential of product cross-contamination

f. Save the cost on equipment

Application case

-Sterile API transfer and subpackage

-Isolator charging and discharging

-Contained dispensing, charging, discharging, sampling and milling

-Containment transfer of sterile rubber plug

-Transfer toxic product

Application

Pharmaceutical Biotechnology Chemical Food Beverage Nuclear CDC

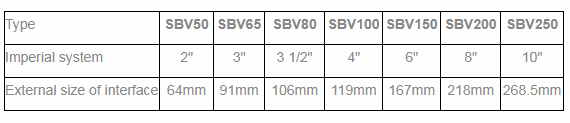

Specification

Standard size: 50mm, 100mm, 150mm, 200mm, 250mm, 300mm

Connections: PN6, PN10, ANSI#150, Tri-Clamp

Customized size: Accept customized non-standard size

bio-equip.cn

Hangzhou Geevo Technology Company Limited is a National high-tech enterprise,located in Yuhang Economic & Technical Development Area, Hangzhou, Zhejiang province.

Integrated with production, research and sale.

Committed to the technology of microbiology test and material containment transfer split butterfly valve.

High attention to the protection of intellectual property rights, insist on technological innovation, having numbers of national patent.

We deliver the highest quality solutions globally across the pharma, chemical, quality control, biotech and food beverage industries."Our product are used widely in disease control, pharmaceutical and biological industries, environment protection organization, quality supervision bureau, biological safety lab, food & beverage, water supply and cosmetic. Product have already been covered in disease control at all levels, the food and drug control, quality inspection, pharmaceutical companies, water plant, food and beverage production enterprises, pharmaceutical research institutions, and also exported well in Europe, Latin America, Africa, Australia and southeast Asia, covering the country such as Brazil, Bangladesh, Turkey, Thailand, Malaysia, Russia, Australia, Zambia, Salvador, Egypt, etc. with good reputation.

Focus on Quality, Service by Heart” as Geevo’s core value. Company not only provides the high quality professional products, but also established a perfect pre-sale, sale, after-sales service system, supply comprehensive support for the customers who the selection of Geevo’s Product.

Main product: sterility test system, microbial limit test, aseptic isolation technology, rapid transfer port(RTP), medium dispensing system, ab valve, split butterfly valve, hydrogen peroxide sterilizer, etc.