Germfree’s bioGO® Mobile Biocontainment Laboratories offer the ideal solution for providing surge capacity for laboratory services during periods of emergency. By utilizing a fully equipped/turnkey Mobile Biocontainment Laboratory, facilities are able to rapidly increase their volume without sacrificing capabilities. Each mobile facility is engineered and constructed to meet or exceed relevant CDC NIH BMBL 5th Edition and World Health Organization (WHO) guidelines for BSL2, 2+, or 3 laboratories.

As experienced in 2020, a pandemic is not only a threat to the health and lives of a population but it also had enormous economic, security, and social impacts. Sound emergency disease surveillance is critical to minimizing the spread and harm caused by an outbreak, epidemic, pandemic or biosecurity threat. The information gathered by a disease surveillance program is critical to prioritizing and strategically deploying preventive health measures, pinpointing high-risk populations, and delivery of targeted therapies, vaccines and supplies, thereby minimizing the impact to life. Quick deployment of laboratory facilities to suspected hotspots further enhances the speed with which our public health professionals can respond. Germfree bioGO® mobile biocontainment laboratories and biosafety equipment can be quickly deployed to serve a wide range of biosafety needs including disease surveillance, public health research, epidemic response mobilization, and biosecurity. Our bioGO® mobile biocontainment cleanrooms are pre-designed and adaptive to provide an offsite built, containment ready solution for advanced applications. Our advanced biosafety equipment is pre-designed and purpose built to meet all user requirements. Germfree is the only manufacturer that provides a single-source, OEM solution for both the laboratory which includes all critical containment equipment. Germfree’s turnkey mobile and modular units meet the most stringent bio-containment requirements and provide critical infrastructure for global health security.

Features

Advanced Design and Engineering

bioGO Biocontainment Laboratories comply with the NIH CDC Biosafety in Microbiological and Biomedical Laboratories (BMBL) 5th edition guidelines. Standard enhancement such as anterooms, directional airflow, HEPA filtered supply air and HEPA filtered exhaust air provide added safety for the operators, samples, and the environment. These enhancements allow the laboratory to meet the World Health Organization (WHO) Biosafety Level 3.

Flexibility of Operations

Our mobile containment laboratories are designed by a team of biocontainment experts to provide the optimal safety for the handling of biologically contaminated materials. This allows the facility to be effectively utilized for manipulating samples required to be handled in a containment laboratory environment.

Efficient Workflow

Germfree’s bioGO Mobile Biocontainment Laboratories are engineered and equipped for the most efficient workflow. The facility is divided into designated work zones. Each zone provides HEPA filtered supply air and the primary containment equipment required for a safe sample flow throughout the laboratory process. Additionally, we strategically place stainless steel workstations, transfer airlocks, storage and supply areas, fold down gowning benches, and staging tables.

Enhanced Ergonomics

HEPA Filtered sample transfer airlocks centrally located in the Laboratory Command Center allow for samples to be processed into the laboratory while maintaining robust Chain of Custody Procedures.

Design Excellence

Germfree’s mobile biocontainment laboratories are designed to be exceptionally durable and easily cleanable. To achieve this, only the highest grade, cleanroom-compatible materials are used in the facility’s construction. The interior walls are Arcoplast, a high performance composite that provides a seamless interior suitable for frequent wash-downs with sanitizing agents as well as gas bio-decontamination. The floor is seamless Armstrong Medintech® vinyl, coved up the walls for ease-of-cleaning.

All work surfaces are seamless stainless steel with casework designed for gas and vapor phase decontamination. Surfaces are coved for easy spill cleanup and sanitization. Edges are rounded and polished to avoid snagging Personal Protective Equipment (PPE).

bioGO® Laboratories are designed to be powered from shore power and are equipped with an automatic transfer switch for integration to locally available generators to provide redundancy in case of power outages or fluctuations.

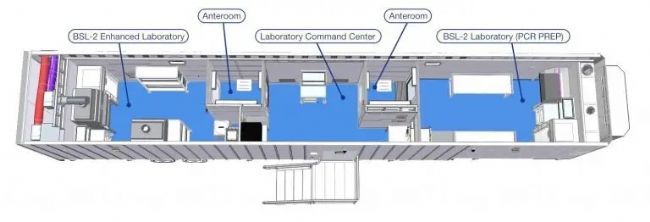

Layout

BSL-2 Enhanced” Laboratory:

This “BSL-2 Enhanced” Laboratory area exceeds BMBL 5th edition Laboratory Facility guidelines as well as World Health Organization (WHO) guidelines. The room air is both supplied and externally exhausted through HEPA filters. The room is equipped with two (2) Class II, Type A2 Biological Safety Cabinets to protect the product and personnel. One of the Class II Type A2 Biological Safety Cabinets is exhausted to the exterior through a HEPA Filter in case solvents are required for processing samples.

Ample storage space is provided by the custom casework as well as an integrated refrigerator and freezer. All casework is stainless steel with seamless welds, coved corners and radiused edges and is compatible with all standard gas and vapor decontamination systems.

BSL-2 Laboratory:

The room is supplied with HEPA filtered air and the return air is HEPA filtered before being recirculated to other areas of the laboratory. Ample storage space is provided by the custom casework as well as an integrated refrigerator and freezer. All casework is stainless steel with seamless welds, coved corners and radiused edges and is compatible with all standard gas and vapor decontamination systems.

Anterooms 1 and 2:

These rooms serve as an air break to the trailer exterior and as a space for personnel to don their Personal Protective Equipment (PPE). The area is equipped with shelves for storing PPE, a hand washing sink, eye wash station, and a fold down gowning bench. The anteroom is maintained at positive pressure relative to the command center to provide an additional barrier to the air cascading into the BSL-2 laboratories. Pressure gauges at each door display room pressures, and have alarms to indicate unsafe conditions due to changes in the differential pressures between the rooms. All interior doors can be operated hands-free. Interlocks prevent both anteroom doors from being open simultaneously.

Laboratory Command Center:

The Laboratory Command Center serves as the main entrance to the Mobile Biocontainment Laboratory and the main entrance door is equipped with the proper security for your application. Pass-throughs are accessible from this environment without requiring the donning of PPE to introduce material to/from the laboratory.

Equipment

Germfree’s bioGO Mobile Biocontainment Laboratories are delivered fully-equipped for ready for on-site commissioning. The standard configuration consists of:

BSL-2 Laboratory

- Custom casework provides ample storage space

- Standard laboratory refrigerator

- Standard laboratory freezer

- The preparation areas consist of stainless steel countertops with seamless welds, coved corners and radiused edges

BSL-2 Enhanced” Laboratory

- Two (2) Germfree Class II Type A Biosafety Cabinets

- Custom casework provides ample storage space

- Standard laboratory refrigerator

- Standard laboratory freezer

- Stand-up autoclave

- Stainless steel countertops with seamless welds, coved corners and radiused edges

Laboratory Command Center

- Two material pass boxes including (1) with HEPA-purge pass-through connecting the Command Center and the “BSL-2 Enhanced” Laboratory Allows the transfer of materials from either of the laboratories into the Laboratory Command Center or vice-versa while maintaining containment

- Interlocked doors assure that the airlock is never open on both sides simultaneously

- HEPA-purge cycle removes particulates within the airlock, achieving ISO Class 5 conditions before the materials are removed

- Stainless steel countertops with seamless welds, coved corners and radiused edges

- Stainless steel casework

- Security, Data and Environmental Monitoring are all accessible from the office area (see related sections)

Anterooms

- Shelves for storing PPE

- Stainless steel hand washing sink

- Fold down gowning bench

MEP

Mechanical Specifications

A heating, ventilation and air conditioning (HVAC) system is installed in the bioGO facility. The HVAC system is engineered to maintain a comfortable working temperature and humidity, and provides an inward flow of air into the BSL-2 laboratories. In the “BSL-2 Enhanced” Laboratory, the mechanical ventilation also prevents recirculation to spaces outside of the laboratory. The variable capacity, 11 Ton HVAC system is designed for the rigors of a fully exhausted “BSL-2 Enhanced” Laboratory in a package that has been proven to handle the challenges of a mobile platform.

Electrical Specifications

Connections for utility power and/or auxiliary generator inputs are provided via transfer switch. Diesel electric generator packages are optionally available and can be supplied by local equipment rental companies.

- 65kVA @208V, 3PH, 60Hz, 300A

- Single point connection

- Shore power inputs are provided

Plumbing Specifications

- (2) Stainless Steel Sinks, one in each anteroom

- Includes emergency eyewash

- 86 Gal on Board fresh water tank, monitor

- Compatibility for connection to a water utility tap

- 2.4 kW on-demand electric water pump

- (2) 55-Gal gray water tanks, gravity drained, monitor

- Gravity drained or storage for batch dumping

- PEX supply and CPVC drain lines

- Single Point of connection

Controls, Communications & Recording Systems

- Communication Ports (12)

- Intercom System

- Fire / Burglar System

- BMS – Environmental Monitoring

- Cameras and Monitors

- Digital video cameras and a digital video recorder (DVR) provide perimeter

- security. Interior and exterior cameras provide live local video.

- CCTV system (8 cameras, DVR capable of recording 30 days of video)

Other

Testing & Quality Control

Germfree’s bioGO Quality Process is designed to evaluate performance as well as fit and finish of every system on our mobile platform. Evaluation and testing is conducted on all components and aspects of the facility.

Germfree’s Quality Control Team employs a checklist- based system during a rigorous trial period. All systems are thoroughly vetted and documented in real world conditions before the bioGO is allowed to leave our manufacturing facility.

Germfree’s commitment is to provide a complete, standalone facility with zero defects, ready and installed with complete confidence at our customer’s site.

Installation

Prior to delivery of the bioGO Mobile Facility, Germfree’s service department will work with you to determine what site work needs to be completed before installation can occur.

Pre-installation Consultation can include: Location of the unit, power supply, data cables and integration, and fresh/waste water connections.

Germfree technician/s will be on-site after delivery to assist with installation, setup, and to provide training on the startup and daily operation of the facility.

Cleaning & Bio-decontamination

bioGO Mobile Facilities receive a thorough, professional cleaning before they are deployed. Germfree has validated a bio-decontamination process that can be performed prior to shipping or on location that consists of triple cleaning followed by decontamination via vaporized / ionized hydrogen peroxide (VHP/IHP).

Triple Clean:

Germfree’s process involves three separate, consecutive cleanings of the facility. Each pass involves a thorough wipe down of all surfaces. The first application uses a germicidal detergent with the second and third applications using a sporicidal agent. PECs and casework are wiped down with a 70% IPA following each cleaning.

VHP / IHP:

Germfree’s validated bio-decontamination process uses either vaporized hydrogen peroxide (VHP) or ionized hydrogen peroxide (IHP).

Documentation

Each mobile laboratory is delivered with a full set of as built drawings. Additional documentation, if necessary, can be requested from your project manager.

Standards & Codes

Germfree’s bioGO Mobile Biocontainment Laboratories meet or exceed the requirements of the CDC NIH BMBL 5th edition for BSL-2 Laboratories. Via enhancements beyond BMBL requirements, the bioGO Mobile Biocontainment Laboratory units comply with the WHO Laboratory Biosafety Manual for BSL-3 laboratories.

Additionally, Germfree’s bioGO Mobile Biocontainment Laboratories meet ISO 7 cleanroom requirements according to ISO 14644 by incorporating fan powered HEPA terminal units with low wall air returns. The units are engineered for precise HVAC, airflow, air pressure, balance strategies, and proper positioning of primary engineering controls within the laboratory.

Project Management

A dedicated project manager will oversee all aspects of your laboratory purchase from order through delivery. In so doing, it is possible to guarantee a seamless transition into your bioGO® Mobile Biocontainment Laboratory